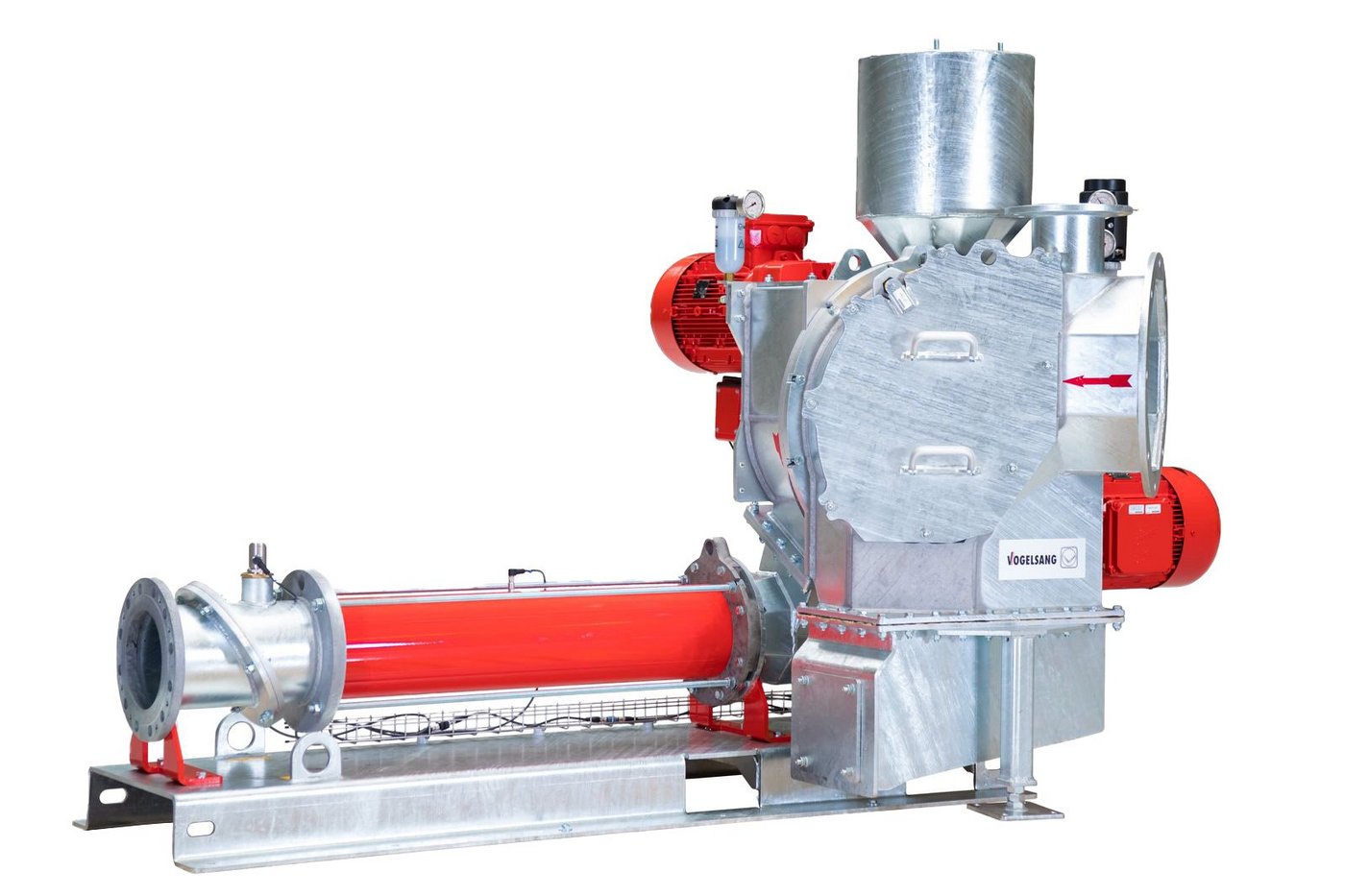

Service and maintenance of the PreMix solid matter feeder

Easy and quick service on site

During the development of the PreMix solid matter feeder, attention was paid to ease of service and maintenance. All necessary work including the replacement of parts subject to wear can be done quickly and easily on site. This keeps interruptions to operation to a minimum.

The innovative pivoting mechanism of the CC series allows maintenance and parts to be replaced on the PreMix pump unit without the need to dismantle parts of the pipes, as is often the case with progressive cavity pumps. The entire stator-rotor unit is simply pivoted upwards or to the side – depending on the local circumstances. The space required and the time for service work is reduced significantly. The cutter is easily accessible due to its generously dimensioned service flap. The cutting blades and cutting screen can be changed in a few simple steps. The proven Quality Cartridge is used to seal the drive shaft. This saves time during a sealing change, avoids installation errors and improves safety.