The customized and modular industrial grinder

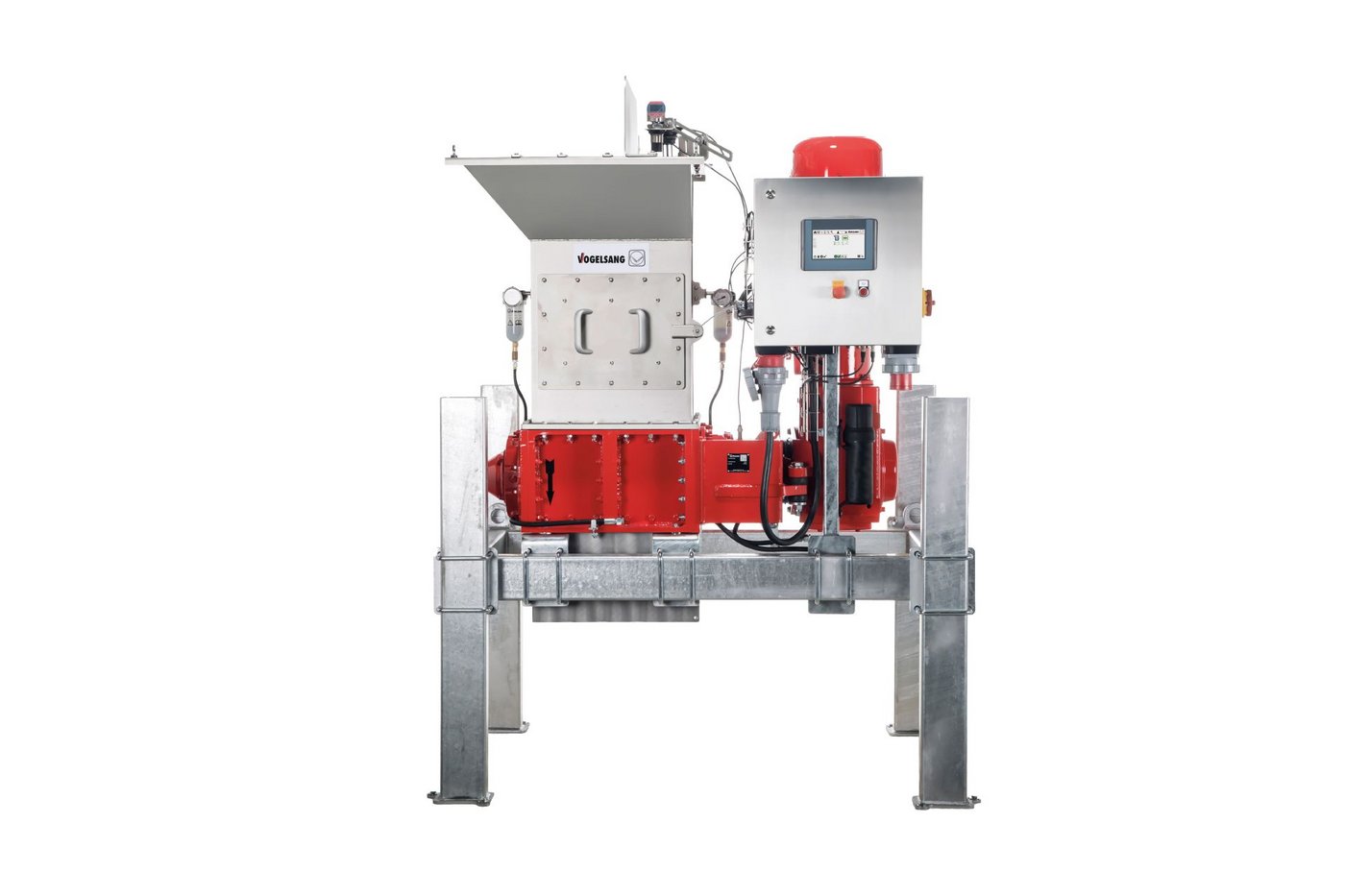

RedUnit

- Customizable through modular design

- Compact and sturdy

- High up-time thanks to quick and easy service

- Added safety due to cartridge mechanical seal technology

- Low electricity consumption

Cuts a big deal down to size

The RedUnit: adaptable, heavy-duty machines for particle reduction and pumping

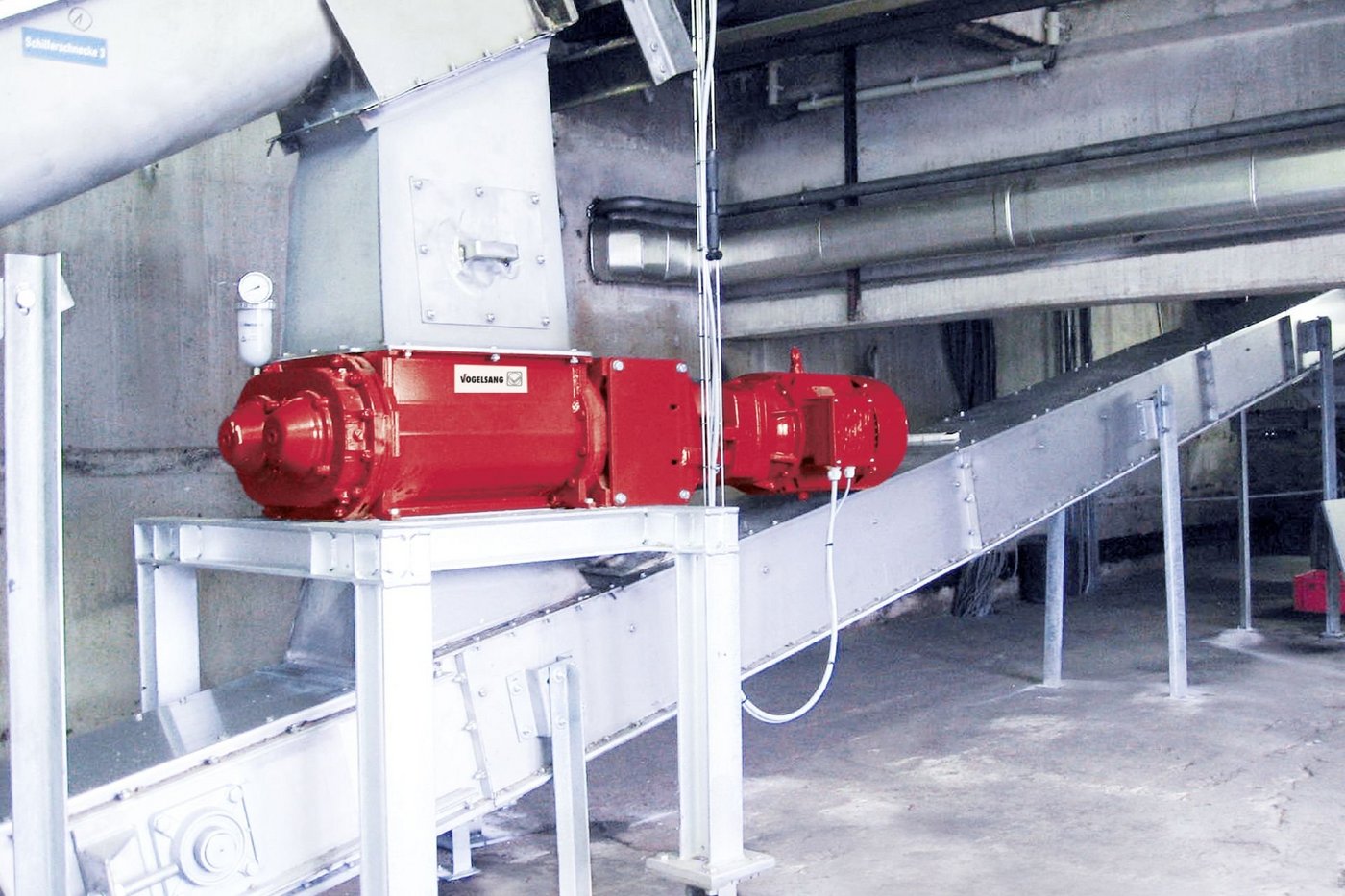

The RedUnit is Vogelsang’s all-in-one solution for shredding and pumping tough materials in a single step. It’s a flexible system that’s custom-built to meet each client’s specific needs, designed for the most demanding industrial applications.

With the RedUnit, high-volume dry solids can be either coarsely shredded or finely ground—depending on the requirements—making them easier to process for further use.

Energy Efficient & Low Maintenance: Unlike systems that require separate pumps or screw conveyors between shredding stages, the RedUnit is a complete system, reducing electricity use and simplifying operations. Vogelsang’s Quality Cartridge sealing technology ensures all seal components are replaced at once, making maintenance quick and hassle-free.

Easy Installation & Smart Control (Optional):

For even greater convenience, the RedUnit offers a plug-and-play option with an intelligent control system. It can be installed by simply connecting a power cable. A touchscreen display provides an overview of all components and allows users to adjust settings based on their specific application needs.

The essential industrial grinder

RedUnit XRL136

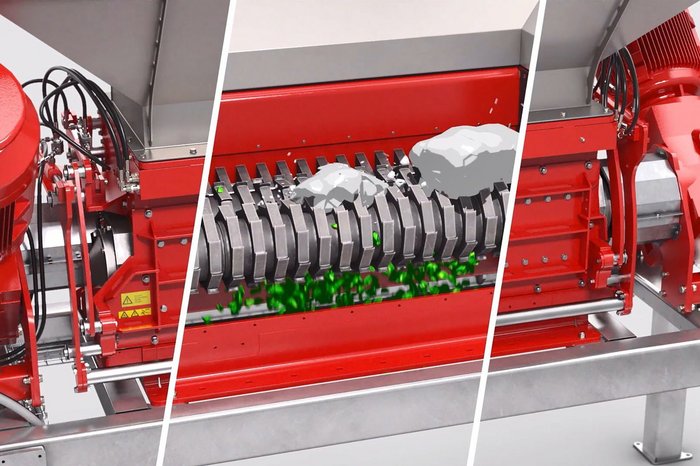

The RedUnit XRL136 series is a twin-shaft grinder designed for efficiently shredding soft and breakable solids like fruits, vegetables, and animal by-products. It operates at a lower torque level, making it ideal for these types of materials.

With a maximum inlet size of 280 mm x 320 mm, it can process materials up to 150 mm in diameter. Tough, brittle components are ground down, while other solids are shredded for easier handling. To customize performance, it offers ripper rotors with different cutting widths, allowing adjustments based on the material type and desired particle size.

The universal grinder for industrial applications

RedUnit XRL186

The RedUnit XRL186 series is Vogelsang’s most versatile grinder, designed for medium to high-volume processing with a maximum capacity of 60 cubic meters per hour. It efficiently grinds organic materials like bones, intestines, and pork rinds, but it’s also tough enough to handle inorganic materials such as plastics, metal cans, and drywall. Built for strength and reliability, this grinder minimizes downtime with Vogelsang’s QuickService design, making maintenance fast and hassle-free.

The industrial grinder for the rough stuff

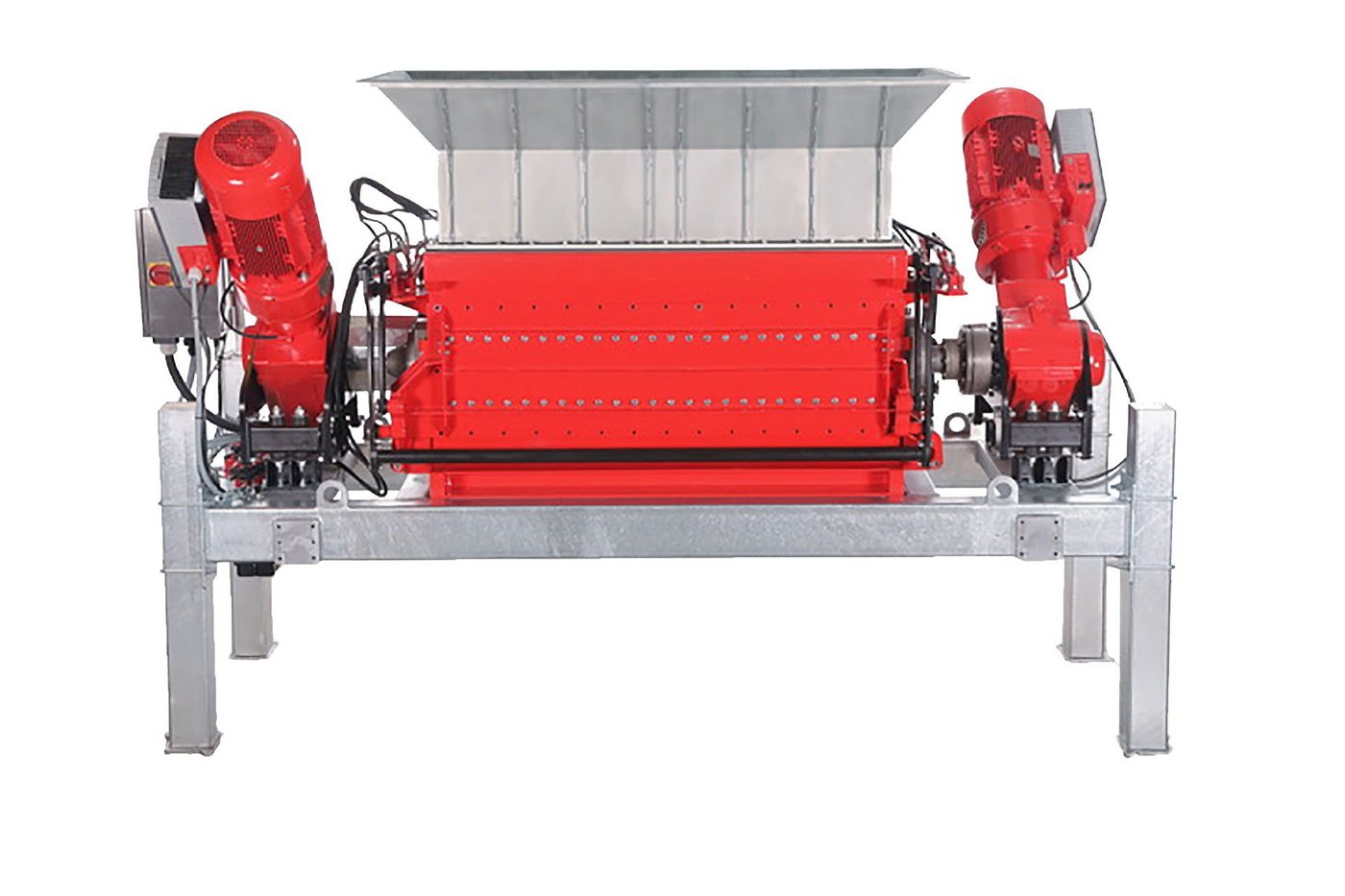

RedUnit XRL260

The Vogelsang RedUnit XRL260 is a powerful twin-shaft grinder built for tough jobs. With a high processing capacity of up to 100 tons per hour, it's ideal for quickly handling large, tough materials like whole carcasses from cows, pigs, and poultry. It’s also effective for processing organic waste and working in the recycling industry, all powered by two 37 kW geared motors.

One of its standout features is an innovative service design, which allows the rotor shafts to be removed and replaced from the side without having to take apart other equipment like conveyor belts. This makes it easy to remove contaminants and minimizes downtime, keeping production running smoothly.

The essential industrial grinder

RedUnit XRL136

The RedUnit XRL136 series is a twin-shaft grinder designed for efficiently shredding soft and breakable solids like fruits, vegetables, and animal by-products. It operates at a lower torque level, making it ideal for these types of materials.

With a maximum inlet size of 280 mm x 320 mm, it can process materials up to 150 mm in diameter. Tough, brittle components are ground down, while other solids are shredded for easier handling. To customize performance, it offers ripper rotors with different cutting widths, allowing adjustments based on the material type and desired particle size.

The universal grinder for industrial applications

RedUnit XRL186

The RedUnit XRL186 series is Vogelsang’s most versatile grinder, designed for medium to high-volume processing with a maximum capacity of 60 cubic meters per hour. It efficiently grinds organic materials like bones, intestines, and pork rinds, but it’s also tough enough to handle inorganic materials such as plastics, metal cans, and drywall. Built for strength and reliability, this grinder minimizes downtime with Vogelsang’s QuickService design, making maintenance fast and hassle-free.

The industrial grinder for the rough stuff

RedUnit XRL260

The Vogelsang RedUnit XRL260 is a powerful twin-shaft grinder built for tough jobs. With a high processing capacity of up to 100 tons per hour, it's ideal for quickly handling large, tough materials like whole carcasses from cows, pigs, and poultry. It’s also effective for processing organic waste and working in the recycling industry, all powered by two 37 kW geared motors.

One of its standout features is an innovative service design, which allows the rotor shafts to be removed and replaced from the side without having to take apart other equipment like conveyor belts. This makes it easy to remove contaminants and minimizes downtime, keeping production running smoothly.

Efficient, Customizable Solids Reduction

The RedUnit from Vogelsang combines both grinding and pumping in one system, offering several advantages over using separate machines. It’s compact, uses less electricity, and is designed for efficiency. Our engineering team customizes each RedUnit to meet the specific needs of every customer and their unique application. Developed as a complete solution, it includes an advanced control system to maximize overall performance. For tough jobs, the industrial grinder can also be made from stainless steel.

The RedUnit is highly reliable, thanks to its easy-to-service components: the RedUnit XRL grinder, the RotaCut wet grinder, a progressive cavity pump from the CC series, and/or a rotary lobe pump from the VX series. This design keeps the system running smoothly with minimal downtime.