The customized and modular industrial grinder

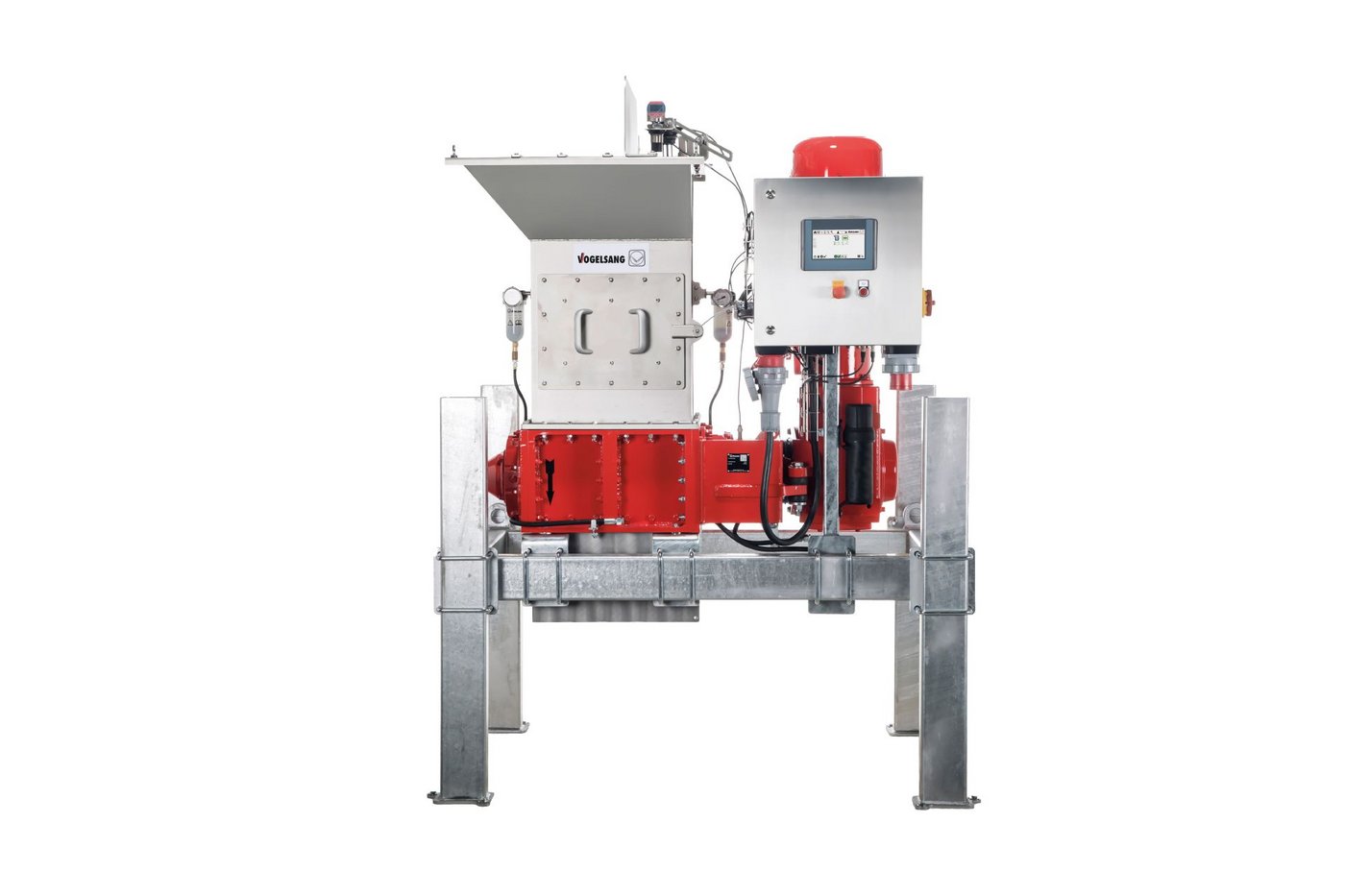

RedUnit

- Individual adaptation through modular design

- Compact and sturdy

- High availability thanks to quick and easy service

- Added safety due to cartridge mechanical seal technology

- Low electricity consumption

Cuts a big deal down to size

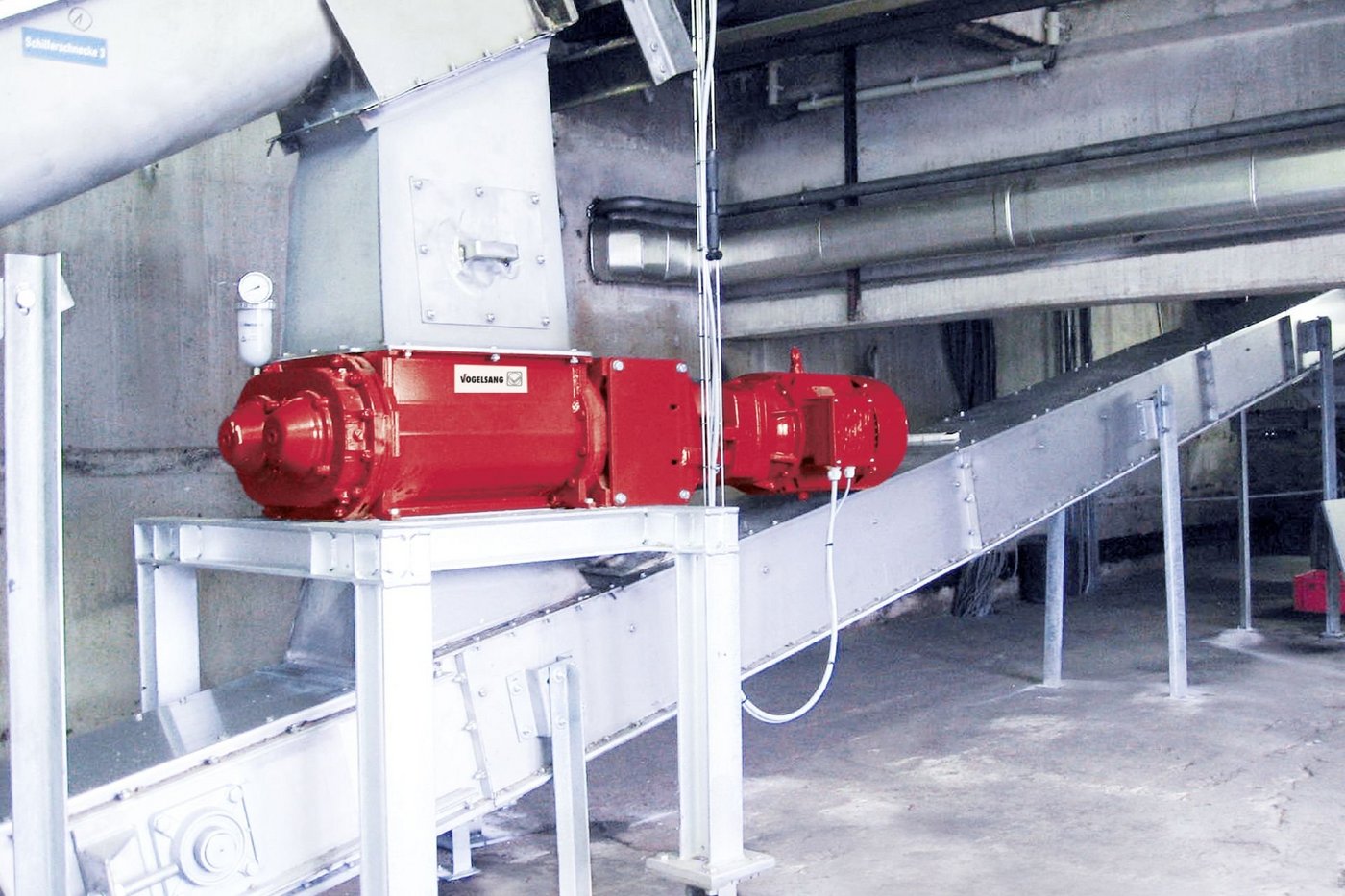

The RedUnit: adaptable, heavy-duty machines mix for particle reduction and pumping

The RedUnit is Vogelsangʼs answer for any process that requires the shredding and pumping of rough media, preferably in one step. A variable system individually put together to exactly match the client’s demands, which Vogelsang has developed especially fort the toughest applications in the industry. With the help of a RedUnit, dry solids of a high volume are either roughly shredded or finely ground – depending on the respective demand – to then be easily treated for further uses.

Energy efficiency and minimum maintenance: The RedUnit is a complete system so there is no need for additional pumps or screw conveyors between the different shredding stages. This leads to lower electricity consumption. Vogelsang uses the most advanced sealing technology in their products: the Quality Cartridge. Thanks to its unique construction, it incorporates all seal components, thus ensuring that all elements are replaced when the cartridge is changed.

Plug and play system (optional): The RedUnit includes an intelligent control system, developed by Vogelsang. Thanks to this, the equipment can be installed in any plant by simply connecting an energy cable. All components of the RedUnit can be visualized on a touchscreen with their technical features, which can be easily set up in accordance with the needs of each application.

Models of the RedUnit

The basic industrial grinder

RedUnit XRL136

The RedUnit XRL136 series is a twin-shaft grinder and optimally suited for processing easily shreddable solids such as fruit, vegetables and offal. It is located in the lower torque range. With a maximum inlet opening of 280 mm x 320 mm, it grinds input materials up to a diameter of 150 mm. Here, the coarse and brittle components are ground, while solids are shredded. Ripper rotors with different cutting widths are available for adaptation to the medium and the degree of comminution.

Downloads

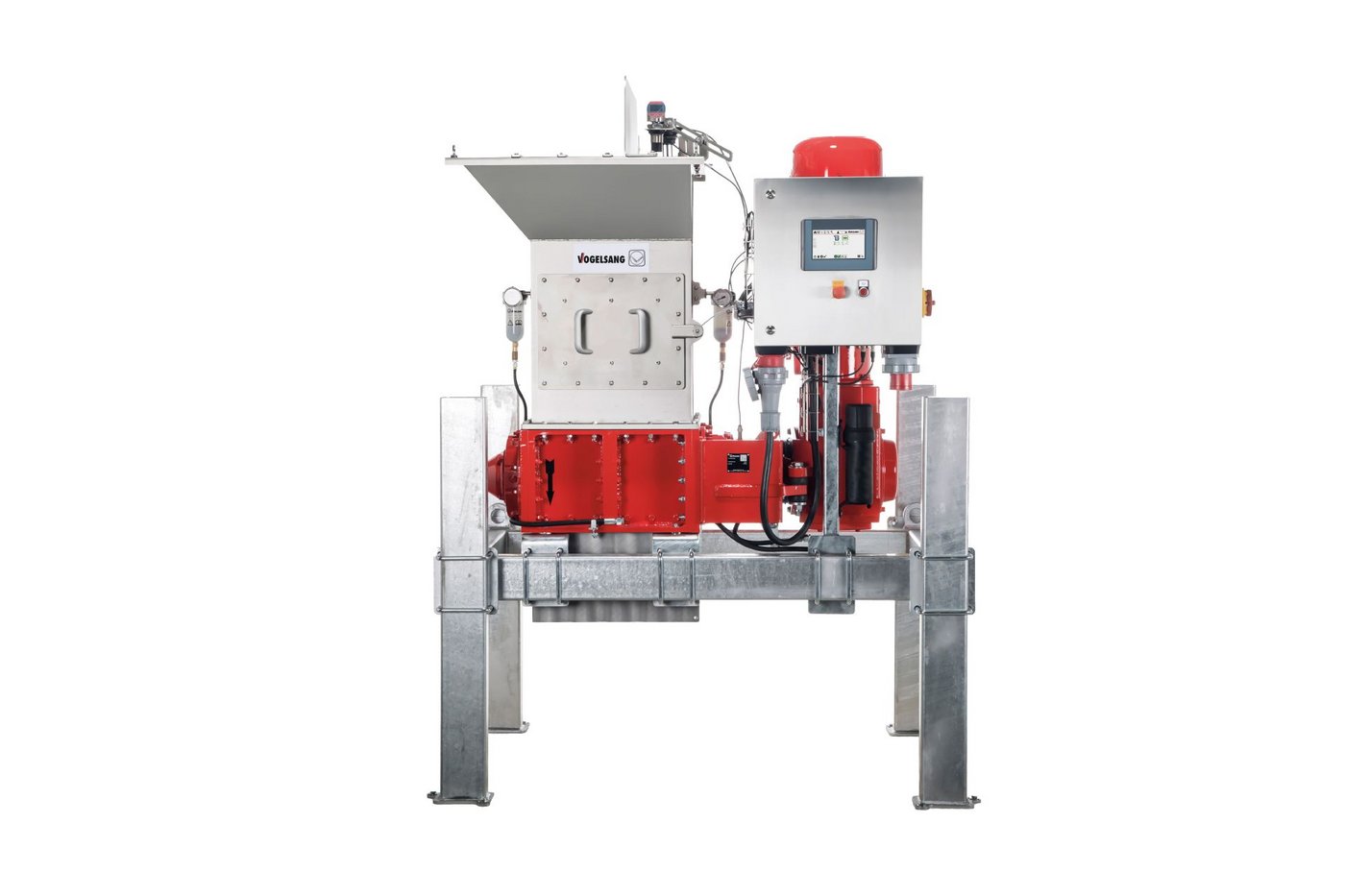

The universal grinder for industrial applications

RedUnit XRL186

The RedUnit XRL186 series is the all-purpose grinder in the Vogelsang portfolio. It is particularly suitable for medium and high volume flows with a maximum throughput of 60 m3/h. It can easily grind organic materials such as bones, intestines and pork rinds. However, this series can also be used to process inorganic materials such as plastics, metal cans and plasterboard. Here, the machine proves to be very reliable and robust. Interruptions to operation due to maintenance work can be reduced to a minimum thanks to the QuickService principle.

Downloads

The industrial grinder for the rough stuff

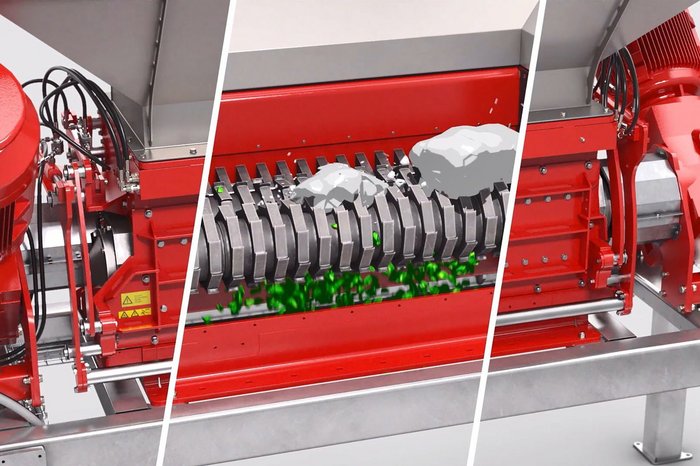

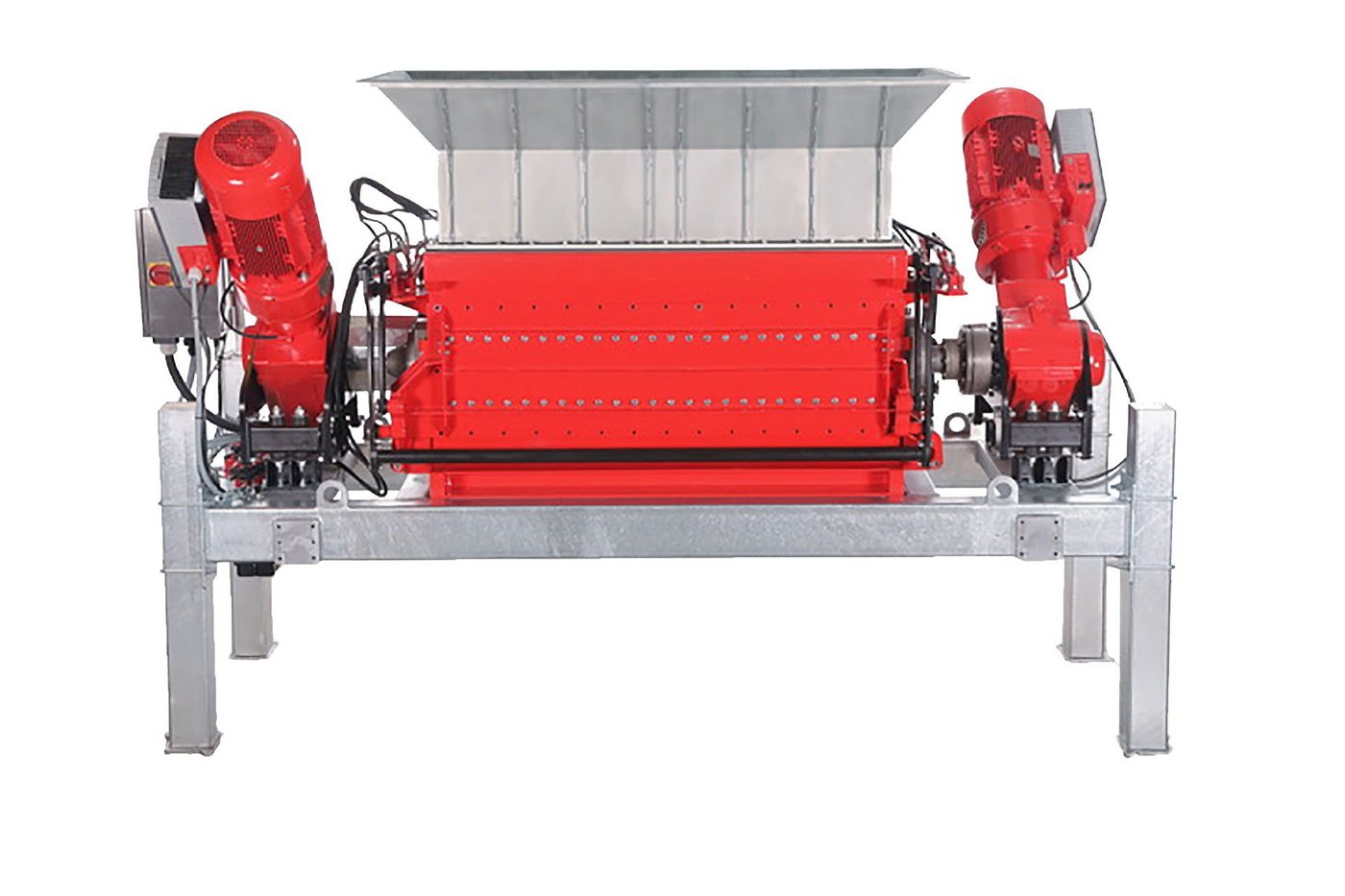

RedUnit XRL260

The Vogelsang RedUnit XRL260 is a powerful twin-shaft grinder with an innovative service concept. With its high throughput capacity of up to 100 t/h, it is used when a variety of large, stubborn materials need to be processed in a short time, such as whole carcasses from cows, pigs and poultry. But the RedUnit XRL260 can also do a great job in processing organic waste and other areas of the recycling industry, driven by two geared motors of up to 37 kW each.

Thanks to its innovative service concept, the rotor shafts can be removed from the side and replaced without having to dismantle feed and discharge systems such as conveyor belts. In the same way, contaminants can also be easily removed, so that interruptions to production are kept to a minimum

Downloads

The basic industrial grinder

RedUnit XRL136

The RedUnit XRL136 series is a twin-shaft grinder and optimally suited for processing easily shreddable solids such as fruit, vegetables and offal. It is located in the lower torque range. With a maximum inlet opening of 280 mm x 320 mm, it grinds input materials up to a diameter of 150 mm. Here, the coarse and brittle components are ground, while solids are shredded. Ripper rotors with different cutting widths are available for adaptation to the medium and the degree of comminution.

Downloads

The universal grinder for industrial applications

RedUnit XRL186

The RedUnit XRL186 series is the all-purpose grinder in the Vogelsang portfolio. It is particularly suitable for medium and high volume flows with a maximum throughput of 60 m3/h. It can easily grind organic materials such as bones, intestines and pork rinds. However, this series can also be used to process inorganic materials such as plastics, metal cans and plasterboard. Here, the machine proves to be very reliable and robust. Interruptions to operation due to maintenance work can be reduced to a minimum thanks to the QuickService principle.

Downloads

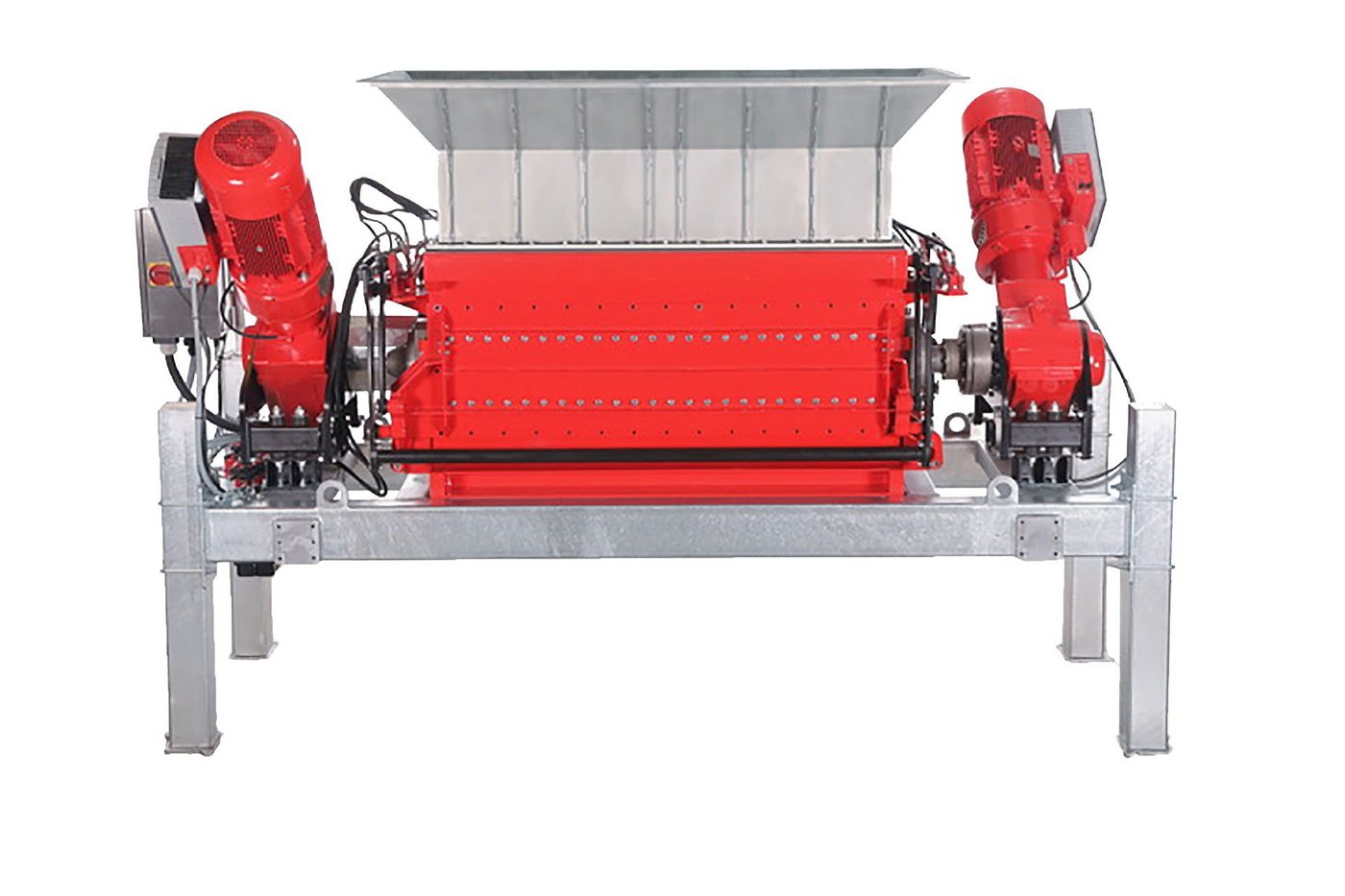

The industrial grinder for the rough stuff

RedUnit XRL260

The Vogelsang RedUnit XRL260 is a powerful twin-shaft grinder with an innovative service concept. With its high throughput capacity of up to 100 t/h, it is used when a variety of large, stubborn materials need to be processed in a short time, such as whole carcasses from cows, pigs and poultry. But the RedUnit XRL260 can also do a great job in processing organic waste and other areas of the recycling industry, driven by two geared motors of up to 37 kW each.

Thanks to its innovative service concept, the rotor shafts can be removed from the side and replaced without having to dismantle feed and discharge systems such as conveyor belts. In the same way, contaminants can also be easily removed, so that interruptions to production are kept to a minimum

Downloads

Features of the RedUnit

Options of the RedUnit

Solids reduction machine for industrial applications

The RedUnit is the grinding and pumping combination from Vogelsang. It has many different advantages compared to the separate products, e.g. its compact design and low electricity consumption. With our engineering department we design every industrial grinder RedUnit specifically customized to the needs of every customer and his specific application. It is developed as a complete engineering unit, including an advanced control system to maximize the efficiency of the complete system. The industrial grinder can be produced in stainless steel for demanding applications.

The RedUnit offers a high availability thanks to the quick and easy concept of its individual components: the grinder RedUnit XRL, the RotaCut wet grinder, a progressive cavity pump of the CC series and/or a rotary lobe pump of the VX series.