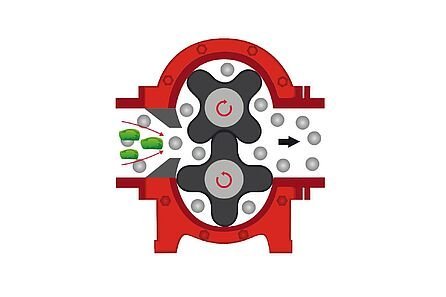

Rotary lobe pump for extreme conditions and high pressures

EP series

- High efficiency due to one-piece housing

- High pressures

- Unparalleled quietness due to high-performance gearbox

- Compliance with industry-specific standards through new sealing options

- AirGap for protection of gearbox and pump chamber

- For media up to 200 °C

Outstanding under high pressure

For maximum performance under extreme conditions: the EP series

Paints, oils, or additives, adhesive or abrasive – in the chemical and petrochemical industry, pumps have to withstand quite a lot.

Extremely low-viscosity media pose almost as great a challenge as high-viscosity liquids, because the flow rates are generally greater and the pressure comparatively high. With the EP series pumps, you can now benefit from these advantages in even more areas of application. This is because they have been specially designed for extreme conditions and continuous high pressures up to 18 bar. They can pump even abrasive, chemically aggressive, and ignitable media with temperatures up to 200° C with the reliability typical of Vogelsang pumps.

Models of the EP series

The pump for high demands and high pressures

Rotary lobe pump EP136

In industry, work is often carried out with demanding liquids, which therefore need to be transported and pumped. Robust and reliable pump systems play an important role here. This is because they come into direct contact with the medium to be processed and are required for a wide variety of production processes. For extreme conditions, such as use in potentially explosive environments or for the pumping of chemically aggressive and hot media, pumps must meet special industry-specific conditions and standards.

Download

The pump for high demands and high pressures

Rotary lobe pump EP136

In industry, work is often carried out with demanding liquids, which therefore need to be transported and pumped. Robust and reliable pump systems play an important role here. This is because they come into direct contact with the medium to be processed and are required for a wide variety of production processes. For extreme conditions, such as use in potentially explosive environments or for the pumping of chemically aggressive and hot media, pumps must meet special industry-specific conditions and standards.

Download

Features of the EP series

Options of the EP series

Modern technology for demanding applications

Demanding applications with abrasive, chemically aggressive and hot media? The EP series has been developed precisely for these applications, e.g. in the oil and gas industry, in the production of sugar, paints and varnishes and in tank farms.

The high-performance gearbox with helical gears generates pressures of up to 18 bar with incomparably quiet running. The low-pulsation pumping reduces wear on the adjacent piping to a minimum.

For high operational reliability, the pump is equipped with an AirGap. This gap provides atmospheric separation between the gearbox and the pump chamber. Even in the event of a leak, no liquid enters the gearbox, but flows off to the outside.

Downloads