Technology for sewage treatment plants

Reliable pump technology and trouble-free wastewater and sludge treatment

Pumps and grinders are built for durability, low energy use, and minimal maintenance. Key components can be replaced on-site by your own team—no need to remove the pump or grinder from the system. For added flexibility, we offer a range of support options, from spare parts delivery and service contracts through our certified distributors. Whether it's consultation, planning, or after-sales service, Vogelsang is your reliable partner for efficient wastewater management.

Reliable pump technology for treatment and pumping of wastewater and slurry

The various media are pumped in sewage treatment plants, including

- Wastewater

- Abrasive primary sludge/raw sludge

- Secondary sludge/surplus sludge

- Mixed sludge

- Organic slime

- Sewage sludge with a high level of dry matter content.

It is important here to use reliable and trouble-free pump technology that is designed for this wide range of media.

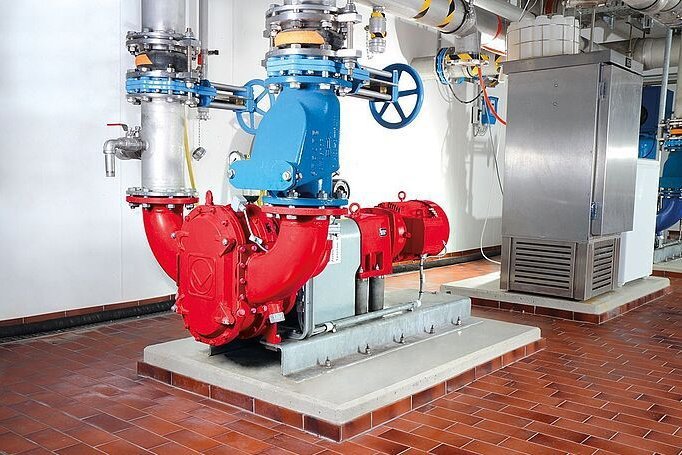

Universal wastewater pump for diverse tasks

Wastewater treatment plants find that Vogelsang pumps make a great standardized option as they work well in numerous applications. The benefit here with the Vogelsang rotary lobe pump is the simple changeover of the direction of flow while the pump capacity remains the same. In this way, using a single pump, wastewater, and sludge can be recirculated between tanks and sump or fecal matter removed from disposal vehicles or tankers filled with sewage sludge. Since the delivery rate is proportional to speed, the efficiency can be variably adjusted via the variable frequency drive while the delivery rate remains the same. By taking into account dry matter content and the viscosity of a medium, pipe diameter, and pipe length, the delivery rate of wastewater pumps and sludge pumps can be adapted individually. In practice, this means feeding of digestion towers, thickening, and drainage is regulated and efficient, yet at the same time, delivery with high pressure or over large distances is also possible. In particular when it comes to circulation in digesters, a high pump capacity makes a positive difference where space requirements are at a premium since little room is often available here for installation of a pump.

Cut, shred and grind for Trouble-free sludge treatment

Wet grinders, regardless of whether they are twin-shaft grinders shredder or macerators, are the efficient solution for reducing the size of foreign matter and separating heavy materials in sewage treatment plants. Unlike integrated grinding units, with separate twin-shaft grinders or macerators, the design can be adjusted to the application avoiding a compromise having to be made for speed between pump operation and the shredder function. In this way, solids and foreign matter is shredded economically, and pumps and other units are reliably protected from foreign matter.

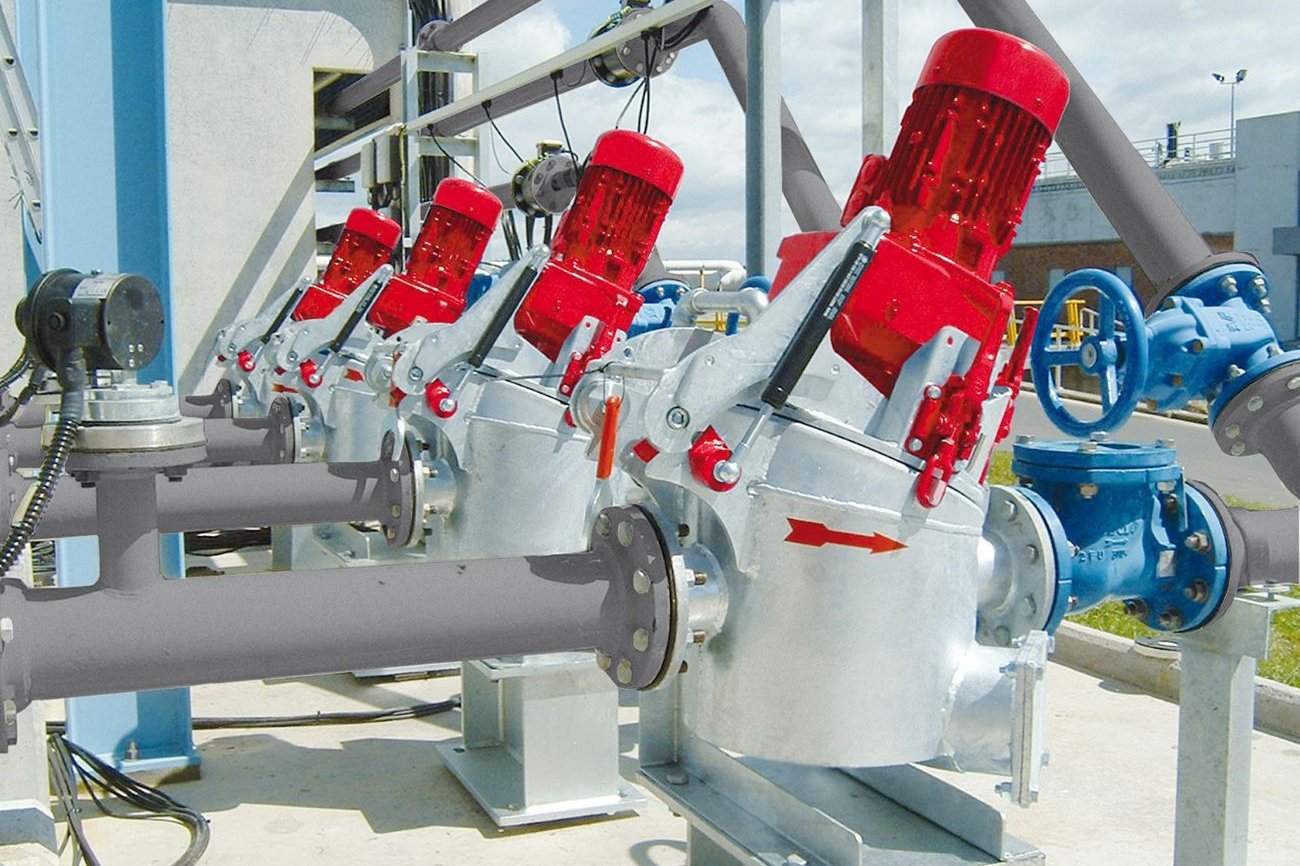

Reliable static thickening and digester circulation

Entangled materials from digesters clog up sludge pumps and block mixers unless they are protected by a shredder/grinder. The XRipper wastewater grinder shreds and reduces entanglements and foreign matter like wood or plastic parts to an easy-to-handle size. This protects pumps from damage and clogging and ensures pipelines remain free. At the same time, twin-shaft grinders based on the contactless principle of operation are low-wearing and will win over customers due to their long service lives.

No chance for entangled materials and floating layers

Hairs and fibers from textiles or cotton swabs cause the formation of entangled materials and floating layers in digesters. Even small amounts of entangled material will render sludge inhomogeneous, increase the required drive power and have a negative effect on drainage and mechanical thickening. Contact-based macerators like the RotaCut are self-sharpening grinders, which even cut fibers and hairs, thereby macerating them. This prevents the formation of entangled materials and prepares sludge homogeneously. It also leads to more uniform operation of decanters and centrifuges and improved draining or thickening.