IQ and VX series: Reliable pumping of latex and copolymers

Case Study: Global Road Technology

Problem

Chemically aggressive media causes leaks in pumps

Solution

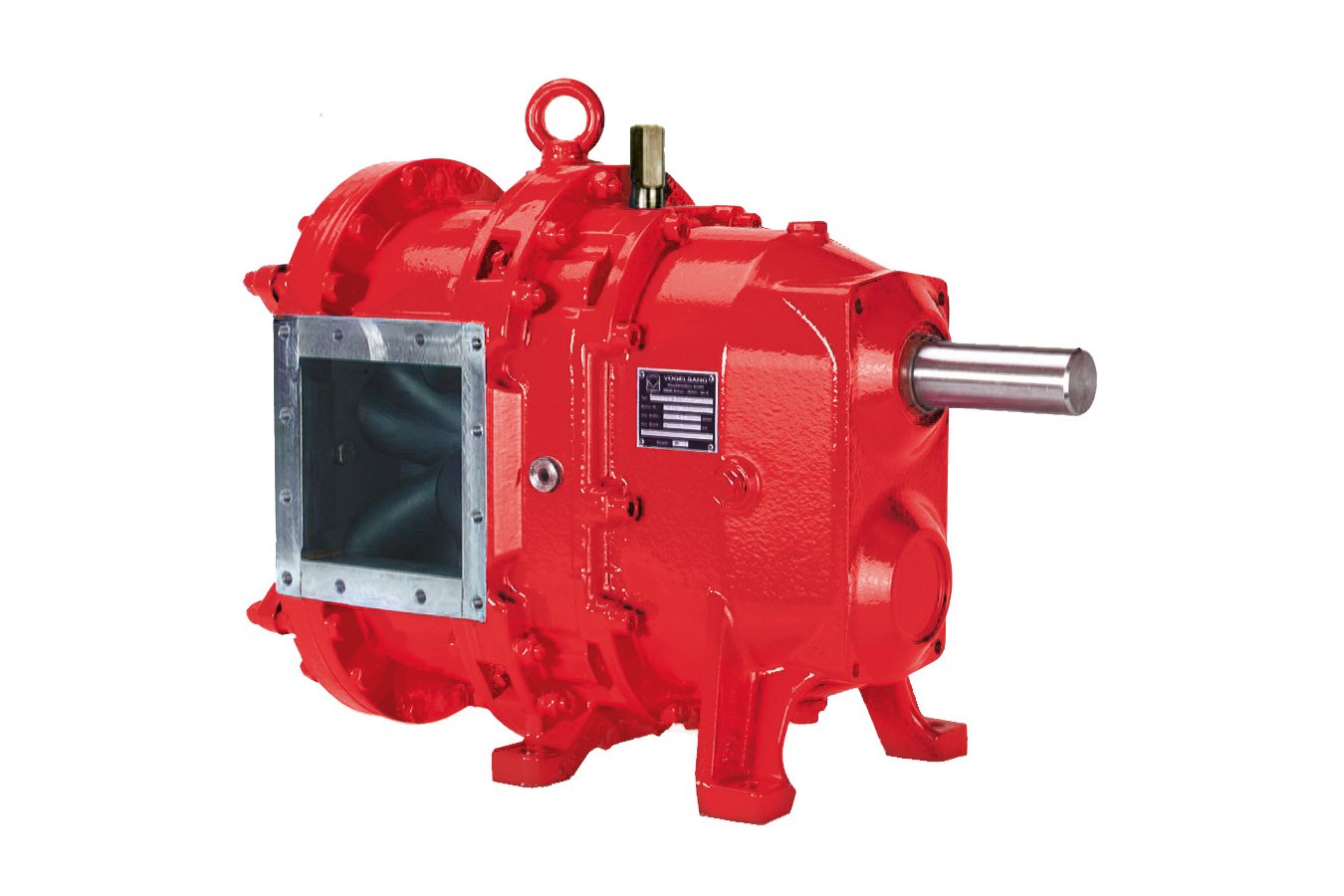

Vogelsang rotary lobe pumps: IQ and VX series

The customer and the problem

Leakages using double diaphragm pumps

Global Road Technology (GRT) is an international company that works with specific products to stabilize the ground and eliminate dust during road construction works.

The company handles very viscous and chemically aggressive media, including mixtures of latex, various acrylic copolymers, silicon emulsions and also numerous additives. A robust and efficient pump technology is required for this kind of work. At first GRT chose double diaphragm pumps; however, these pumps started to have leakages.

The solution

VX and IQ series: Reliable seal technology

In 2014 GRT decided to replace the diaphragm pumps with the Vogelsang VX136-70Q and IQ112-114 pumps. All Vogelsang pumps are equipped with the patented Quality Cartridge mechanical seal. This seal technology and the pulsation free HiFlo lobes provide an extended life and reliable pumping for GRT.

The Vogelsang Quality Cartridge is completely preassembled in the factory; quality approved using computers and is ready for use immediately. Thanks to its unique construction, it includes all seal components where replacing the sealing elements is done in just one step.

The VX series pumps are used in concrete mixing plants of GRT and the IQ series pumps in a mobile unit equipped with a diesel motor to allow easy access to the containers and with the possibility to use it directly in field. The Vogelsang rotary lobe pumps have been in operation for one year and have proved to be reliable providing consistent high performance for GRT thanks to their robust components and sophisticated technology.

Advantages of the VX and IQ series

- Compact design

- Robust and maintenance friendly

- Reliable seal technology

- Insensitive to dry running