RotaCut Macerator Outshines Grinder at Biogas Facility

Case study: Green Cow

Problem

Green Cow, an energy producer in Goshen, Indiana uses manure to generate biogas and other byproducts. To optimize efficiency of the digestion process, solid particle size needs to be consistent around 4-5mm (3/16”). The grinder being used by Green Cow was producing stringy waste that did not meet this requirement and often caused clogs. It turns out that it was the wrong equipment altogether.

The customer

Green Cow Power in Goshen, Indiana takes in manure from five nearby dairy farms – that’s three semi-trailers full every day. The manure, combined with area food waste, is fed into a biogas digester to produce 630 SCFM of biogas and 2200 kW of electricity that is used in the local power grid. The digested liquids and solids are returned to the farms.

The liquid is stored in lagoons to be used as a crop fertilizer, while the solids are used as cow bedding. Hot water that is generated is used to power the digester.

The problem

A twin-shaft grinder from a Vogelsang competitor was being used to reduce manure solids before they entered the pumping process. The high volume of the flow and inconsistent solid contents in the manure would routinely plug up the grinder which caused it to need frequent servicing.

Due to the design of the grinder, replacing the cutter stack and lower bearings was very time-intensive and expensive. Rebuilding the cutter stack required aligning and shimming numerous blades and spacers, an operation that could take hours. Additionally, the twin-shafted grinder was not designed to separate the heavy solids like rocks that get into the manure. The feedstock also contains very stringy fibers which could not be handled by this equipment or cut into the required 3/16” size to maximize digester efficiency.

The solution

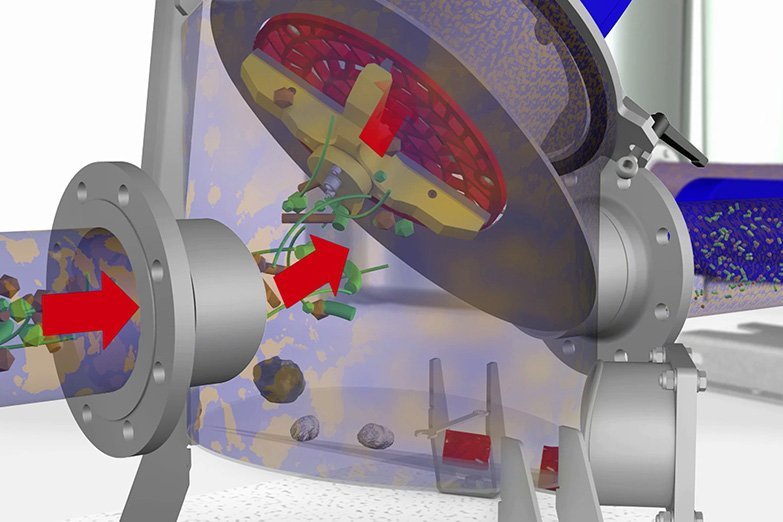

The Vogelsang RotaCut RCX58G is an inline macerator used on the suction side of the submersible pumps that feed the manure/organics mixture into the anaerobic digester tank. The RotaCut design separates the heavy solids including a high volume of gravel and rocks and drops them into a pit. The RotaCut screen then reduces the remaining material into particles of the required size.