The customer and the problem

Case study: Pulp & Paper Mill Pumps

The Customer

One of the world’s leading producers of fiber-based packaging, pulp and paper. Their Georgia-based facility specializes in container board, kraft paper used in countertops, furniture, partitions and shelving, and in unbleached kraft linerboard.

The Problem

The paper company's current pumps were not able to handle black liquor and soap efficiently and were losing their packing, causing spills that had to be cleaned up. In the process, they were seeing potential income floating away with the soap and black liquor byproduct they sold to other companies.

The solution

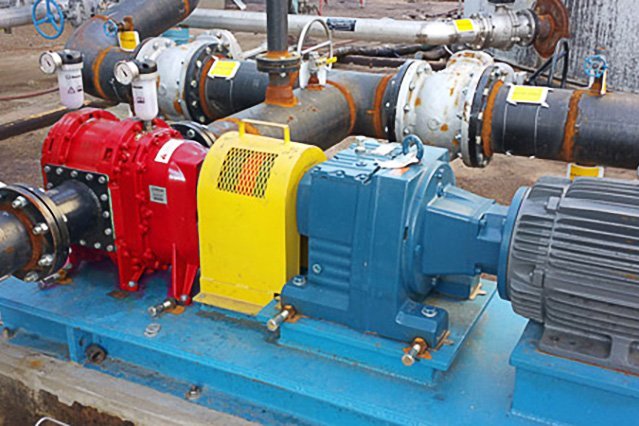

The company's Vogelsang distributor Kirkwood Pumps and Process based in Covington, Louisiana. Kirkwood suggested replacing the failing pumps with the Vogelsang VX Series Rotary Lobe Pump. The new Vogelsang pumps soon became exemplary performers for the company's process.

But the story doesn’t end there.

The improvement caught the attention of the company's customer, a producer of biobased chemicals and specialty polymers. The polymer company buys soap byproduct from our pulp and paper customer for use in their operations. With the old pumps, the demand for soap production was not being meet but with the new Vogelsang pumps efficiency was increased resulting in a higher soap output. The polymer company was so pleased with the results, a meeting was convened between all parties to discuss the benefits of the Vogelsang VX pump with the plan to extent the relationship to other partners and suppliers.

Since then, Vogelsang has supplied VX pumps to more than 10 additional mills so far, with several more proposals in process.