Operation and construction of a modern biogas plant

From Biomass to Sustainable Energy

A biogas plant is constructed so that it provides optimal conditions for biogas production: The biomass is kept in large containers ("digesters") where it ferments in the absence of light and oxygen. This anaerobic fermentation takes place in four stages, during which each specialized bacterium converts the biomass step by step, producing the biogas. These “steps (also called “phases”) are as follows:

- First step: Hydrolysis (digestion of raw materials)

- Second step: Acidogenesis (acidification)

- Third step: Acetogenesis (formation of acetic acid)

- Fourth step: Methanogenesis (formation of methane)

The biogas itself consists mainly of methane and carbon dioxide, but also of numerous other gases such as hydrogen sulfide, nitrogen, oxygen and ammonia. At the end of the fermentation process, you are left with the "digestate" fermentation residue, which can be used in agriculture as fertilizer. This completes the natural cycle; with no other usable by-product, biogas is highly sustainable.

Biogas: the concrete cow

Considering the process steps described above, there is great similarity to the digestive system of a cow - which is why a biogas plant is also known as a concrete cow. In both the biogas plant and the digestive systems of ruminants, bacteria convert biomass into energy. The process in modern biogas plants known as "substrate preparation" is the equivalent of the cow chewing. Hydrolysis takes place in the cow's first stomach (the rumen). The acidification and formation of acetic acid then takes place in the omasum and abomasum, while the energy is generated (i.e. absorbed into the cow's body) in the small and large intestines, as well as the appendix. Another striking similarity is in the solid input material (substrate). Like their cows, many farmers feed their biogas plants with renewable materials such as corn silage and grass silage.

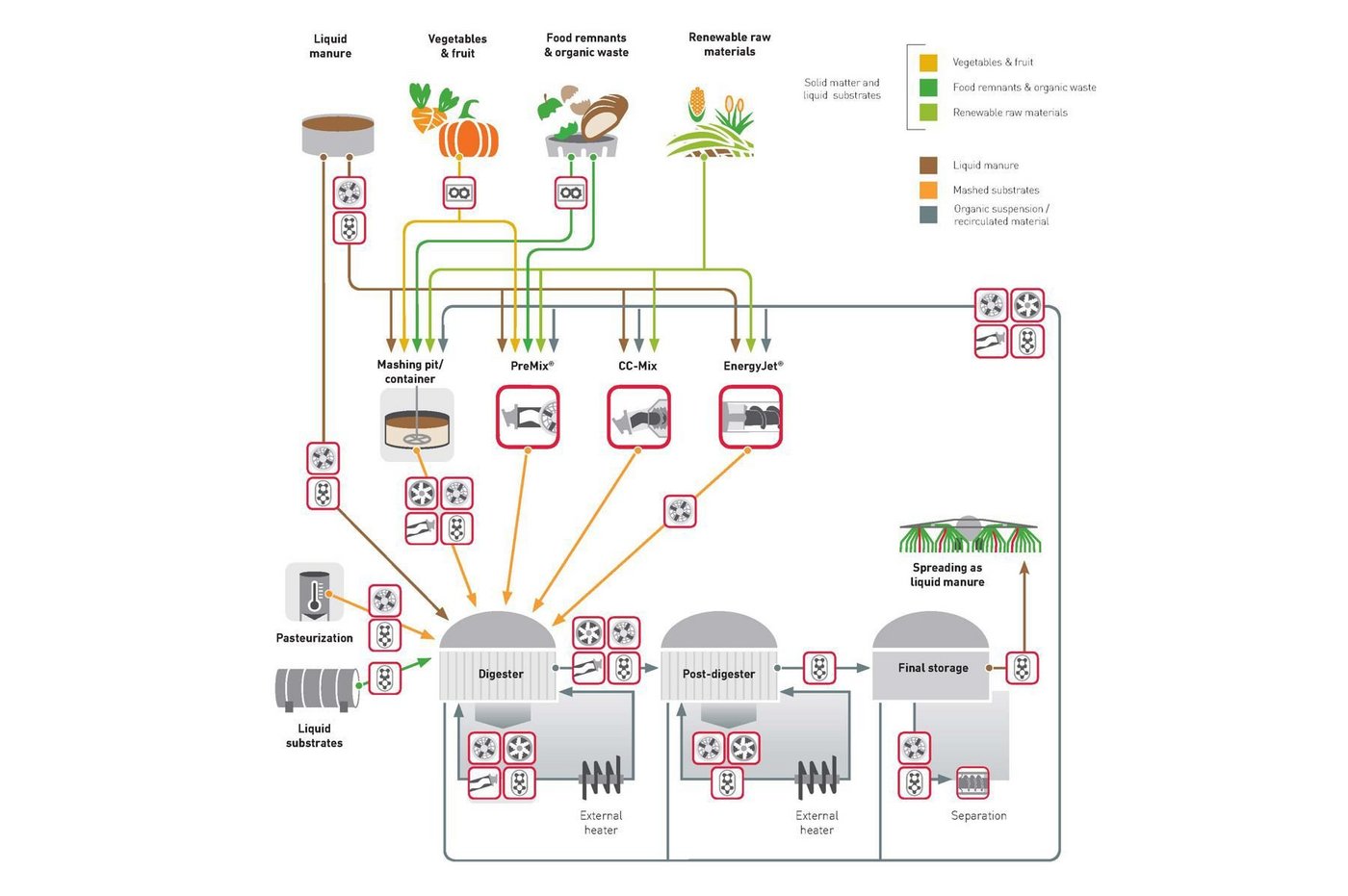

The elements of a biogas plant

Important core elements of every biogas plant are as follows::

- Substrate / solid matter feeding

- Digester tank

- Mixers for mixing in the digesters

- Gas storage

- Fermentation residue storage for the remaining fermented material

- Biogas utilization is generally used for a cogeneration unit or more rarely for gas processing and storage in the network

A cogeneration unit is a gas engine that is coupled with a generator that generates electricity (power) from the biogas energy. Mixers are necessary, because only they can create optimum conditions for the generation of biogas when the digester is mixed well and evenly. The goal of solid matter feeding is to introduce the solid biomass into the digester. Ideally, this is done with low energy consumption and trouble-free operation, regardless of the type of biomass.

The solid matter that can be used in a biogas plant depends on several factors. Basically, the organic content should be very dense, since only this can be converted into biogas. The retention time must also match the solid matter used. Retention time refers to the average time that the biomass spends in the digester until it flows out. If this time is too short, then the bacteria does not have enoughtime to break down most of the solid matter as needed. As a result, the energy contained in biomass is not fully utilized. From a technological perspective, this is not a problem, but it does impact the cost-effective operation of the biogas plant. High energy input materials also do not automatically provide the most economic yield. It is also necessary to consider the costs of the input material and the actual energy that it can provide. Finally, official permission must be requested for the selected biomass.