Rotary lobe pump for every application

VX series

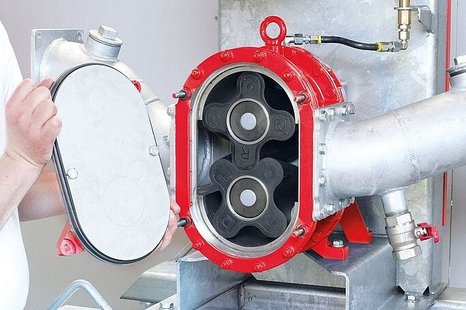

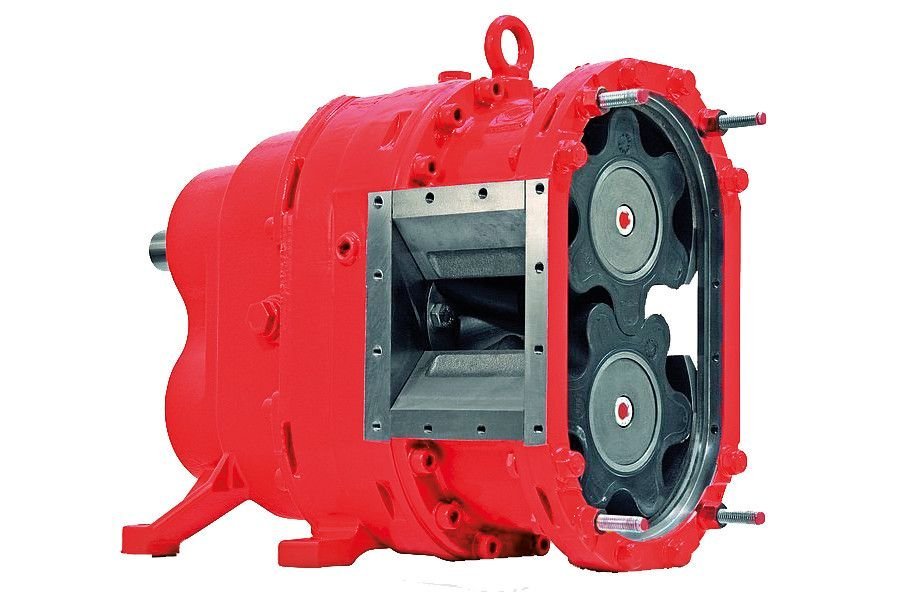

- Easy maintenance, quick on-site service thanks to access to the pumping chamber simply by disassembling the cover

- Cost-effective operation thanks to a high degree of efficiency

- Comprehensive range of features and options

- Self-priming, resistant to dry running and foreign matter

- Long service life

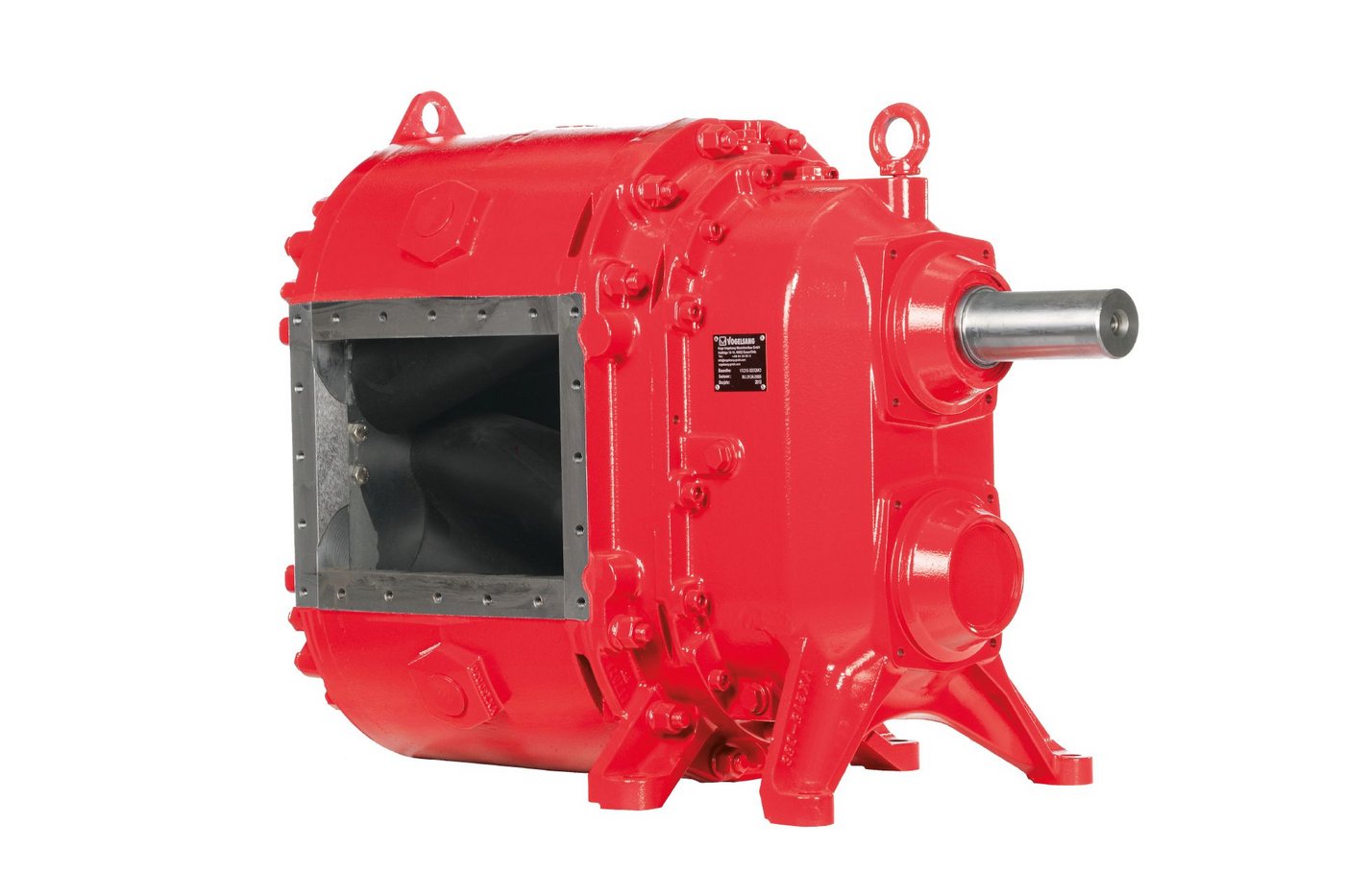

Established rotary power pack

The adaptable VX series for task-oriented pumping

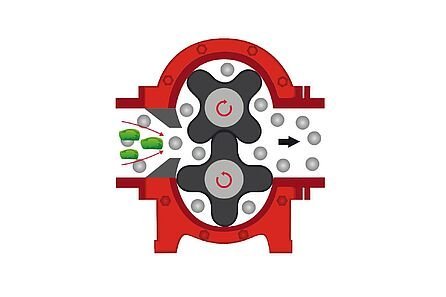

The all-round pump of the VX series is characterized by its compact design and robust properties. She is easy to maintain, self-priming and dry running resistant findable. That‘s why it‘s ideal for media and substances ranging from thin to highly viscous, abrasive or aggressive sive as well as those who react sensitively to shear forces. As a servicefriendly classic rotary lobe pump used worldwide, the VX series pumps are available in five series with up to eight sizes. Depending on the task and performance requirements, a specially designed version of the reliable rotary lobe pump can be assigned for almost any delivery rate and any differential pressure.

The models of the VX series

The small rotary lobe pump

VX100

The VX100 rotary lobe pumps are available in four sizes, offering the advantages of the Vogelsang VX series for small to medium capacities of up to 50 m³/h and pressures up to 10 bar. Special options, such as a sophisticated lightweight concept with aluminum components, a directly flanged electric motor, or the PTB-certified A1 design with flame trap, make the series the ideal solution for simple to highly specialized applications. They are the economic solution for a wide variety of applications in industry, wastewater technology and transportation areas such as bus, boat and trains– particularly where there is a need for self-priming, dry-running-resistant, easy to maintain and efficient pump technology.

Downloads

The compact and universal rotary lobe pump

VX136

The VX136 series stands out for its compact type of construction and its wide range of models and options. Six sizes in 9 different types of construction offer capacities of up to 364 m³/h and enable pressures of up to 12 bar. Rotary lobe pumps in the VX136 series are easy to handle, reliable to operate and easy to maintain, just like all the pumps in the VX series. Special options such as the modular InjectionSystem, radial and axial wear plates, or special materials like ADI, stainless steel or nickel alloys form the basis for a design that is optimally adapted to the specific application. Thanks to this variety of design options, the pumps in the VX136 series have proven their worth over decades in the industrial, wastewater technology, agricultural and biogas sectors, as well as in transport.

Downloads

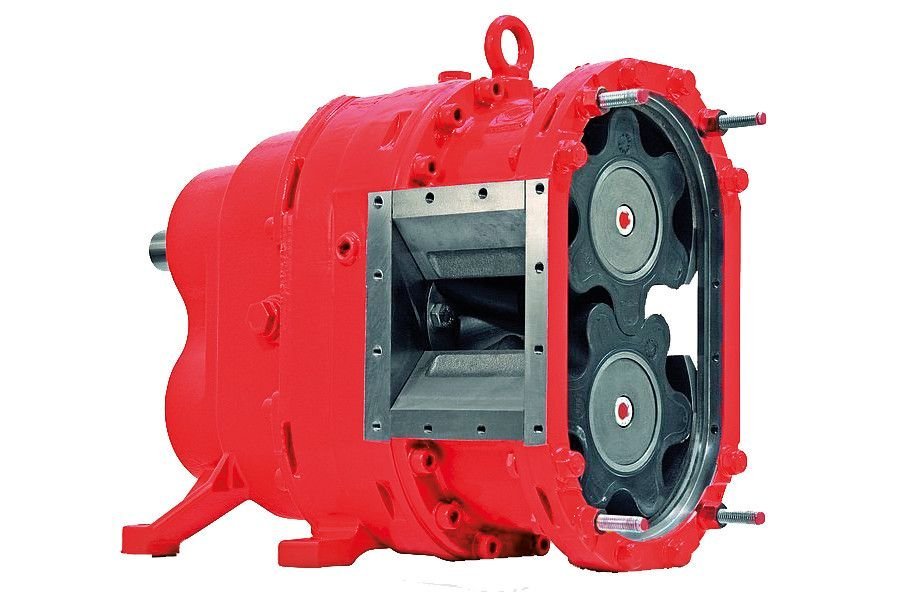

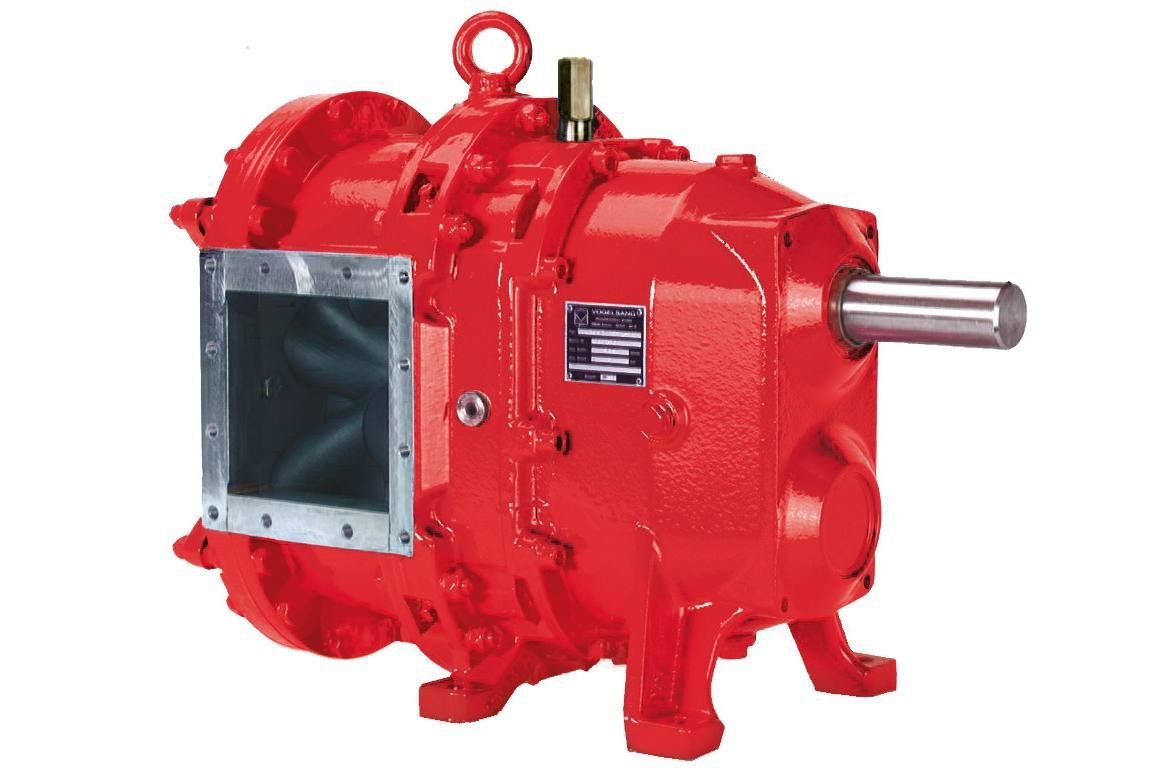

The sturdy and strong rotary lobe pump

VX186

The key feature of the VX186 series rotary lobe pumps is their sturdy and powerful design. Available in eight sizes in 13 different types of construction, they offer capacities of up to 1,025 m³/h and enable pressures of up to 12 bar. This makes them the ideal choice wherever large quantities of abrasive, viscous or aggressive media have to be pumped reliably and safely. Applications include tankers, in industry, biogas plants or wastewater technology. Thanks to equipment characteristics that were developed on the basis of practical experience, such as the wear plate concept, the Universal Drive System or the variety of drive options, the VX186 series is the right choice wherever sturdy and powerful pumping is needed and easy maintainability is just as necessary as a good suction capability and resistance to dry running and foreign matter.

Downloads

The powerful rotary lobe pump

VX215

The VX series in the VX215 range impresses with its large flow rates. Four sizes in 6 different designs allow up to 24,000 l/min or 1,417 m³/h and pressures of up to 8 bar. And at the same time, it is very compact and has a low net weight. Another positive characteristic is its strong resistance to foreign matter thanks to a large free passage of 90 mm. This series can also be fitted with the InjectionSystem as an optional extra. This increases the pumps’ insensitivity to foreign matter. To ensure rapid maintenance, the series is designed according to the QuickService principle. This means that all wetted parts can be changed in the installation position, without dismounting the pump. This makes the VX215 series particularly well suited to pumping tasks that demand power, e.g. in membrane filtration, on tankers or on self-propelled vehicles.

Downloads

The high performance rotary lobe pump

VX230

High capacity in the minimum of space. This is the key characteristic of VX230.Based on four sizes and 6 different designs, it offers outputs of up to 1,234 m³/h against pressures of up to 12 bar. And the model series also features the basic characteristics of the VX series, such as the QuickService principle. This makes maintenance work significantly quicker and easier, and it reduces standstill to a minimum.

Downloads

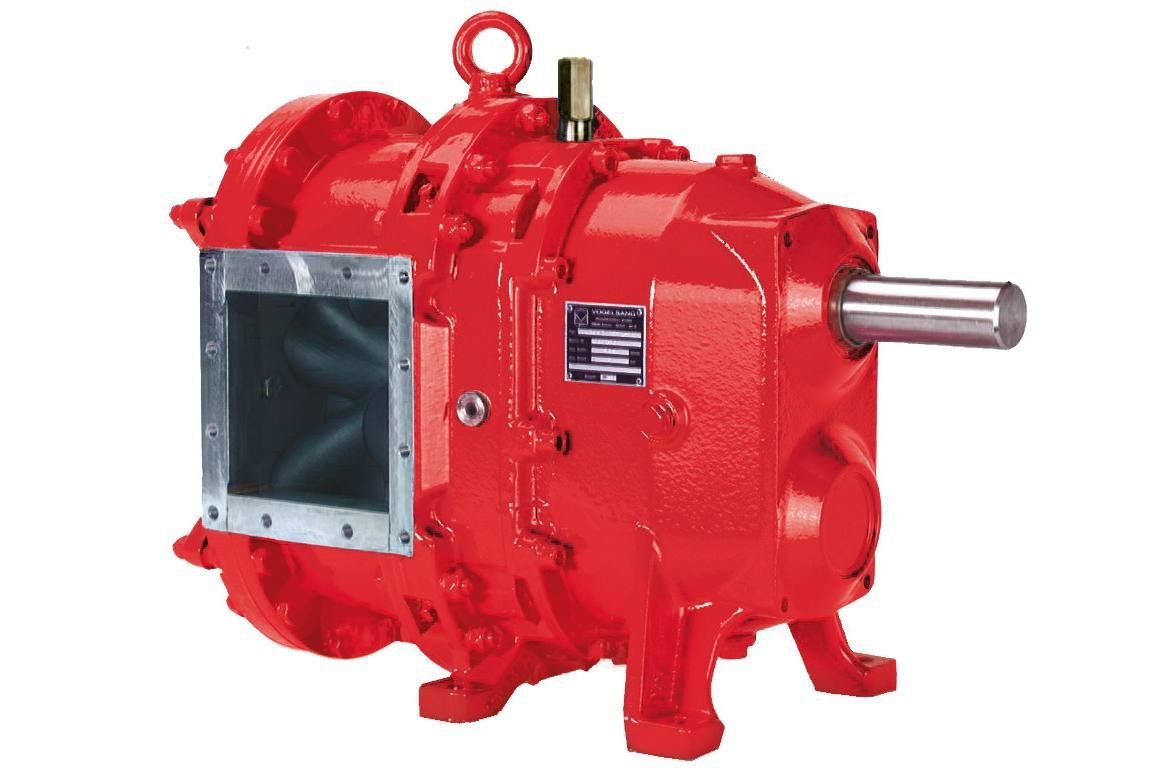

The small rotary lobe pump

VX100

The VX100 rotary lobe pumps are available in four sizes, offering the advantages of the Vogelsang VX series for small to medium capacities of up to 50 m³/h and pressures up to 10 bar. Special options, such as a sophisticated lightweight concept with aluminum components, a directly flanged electric motor, or the PTB-certified A1 design with flame trap, make the series the ideal solution for simple to highly specialized applications. They are the economic solution for a wide variety of applications in industry, wastewater technology and transportation areas such as bus, boat and trains– particularly where there is a need for self-priming, dry-running-resistant, easy to maintain and efficient pump technology.

Downloads

The compact and universal rotary lobe pump

VX136

The VX136 series stands out for its compact type of construction and its wide range of models and options. Six sizes in 9 different types of construction offer capacities of up to 364 m³/h and enable pressures of up to 12 bar. Rotary lobe pumps in the VX136 series are easy to handle, reliable to operate and easy to maintain, just like all the pumps in the VX series. Special options such as the modular InjectionSystem, radial and axial wear plates, or special materials like ADI, stainless steel or nickel alloys form the basis for a design that is optimally adapted to the specific application. Thanks to this variety of design options, the pumps in the VX136 series have proven their worth over decades in the industrial, wastewater technology, agricultural and biogas sectors, as well as in transport.

Downloads

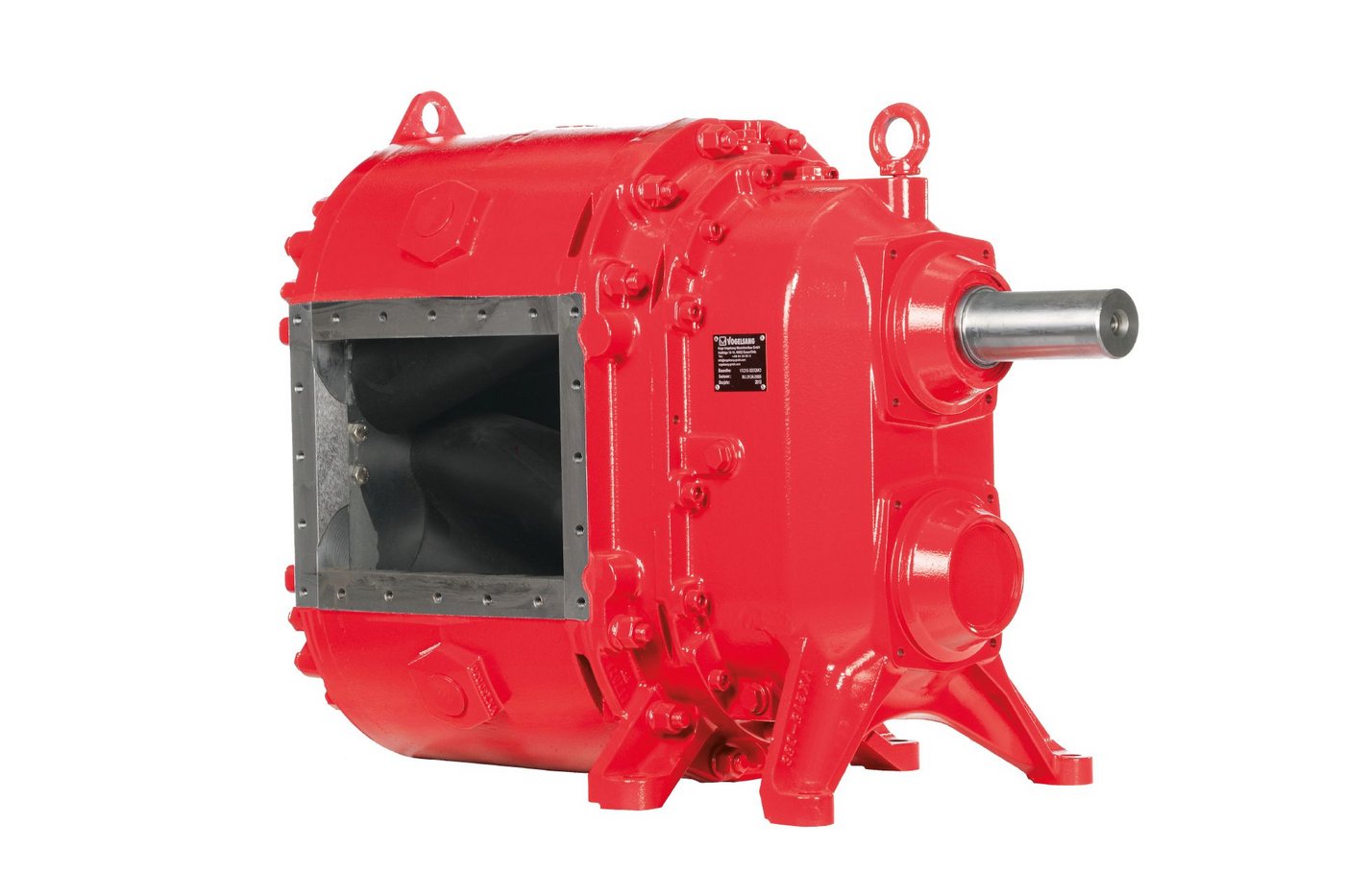

The sturdy and strong rotary lobe pump

VX186

The key feature of the VX186 series rotary lobe pumps is their sturdy and powerful design. Available in eight sizes in 13 different types of construction, they offer capacities of up to 1,025 m³/h and enable pressures of up to 12 bar. This makes them the ideal choice wherever large quantities of abrasive, viscous or aggressive media have to be pumped reliably and safely. Applications include tankers, in industry, biogas plants or wastewater technology. Thanks to equipment characteristics that were developed on the basis of practical experience, such as the wear plate concept, the Universal Drive System or the variety of drive options, the VX186 series is the right choice wherever sturdy and powerful pumping is needed and easy maintainability is just as necessary as a good suction capability and resistance to dry running and foreign matter.

Downloads

The powerful rotary lobe pump

VX215

The VX series in the VX215 range impresses with its large flow rates. Four sizes in 6 different designs allow up to 24,000 l/min or 1,417 m³/h and pressures of up to 8 bar. And at the same time, it is very compact and has a low net weight. Another positive characteristic is its strong resistance to foreign matter thanks to a large free passage of 90 mm. This series can also be fitted with the InjectionSystem as an optional extra. This increases the pumps’ insensitivity to foreign matter. To ensure rapid maintenance, the series is designed according to the QuickService principle. This means that all wetted parts can be changed in the installation position, without dismounting the pump. This makes the VX215 series particularly well suited to pumping tasks that demand power, e.g. in membrane filtration, on tankers or on self-propelled vehicles.

Downloads

The high performance rotary lobe pump

VX230

High capacity in the minimum of space. This is the key characteristic of VX230.Based on four sizes and 6 different designs, it offers outputs of up to 1,234 m³/h against pressures of up to 12 bar. And the model series also features the basic characteristics of the VX series, such as the QuickService principle. This makes maintenance work significantly quicker and easier, and it reduces standstill to a minimum.

Downloads

Features of the VX series

Options of the VX series

The VX series for your market