The progressive cavity pump as a particularly resistant pump

Progressive cavity pumps

Progressive cavity pumps belong to the rotary positive displacement pumps. The basic principle of the progressive cavity pump was invented in 1930 and is based on a rotor rotating in a stationary stator. The rotor has the shape of a screw conveyor with a large pitch and flight depth as well as a small core diameter and rotates "eccentrically" in the stator. The stator, in turn, has the shape of a matching, but a doubled thread worm with twice the pitch. Due to the geometry and the eccentric rotation of the rotor, cavities are formed in which the medium is enclosed and evenly conveyed from the suction to the pressure side; the second gear of the stator is used as a conveying channel for the medium. Based on this conveying concept, progressive cavity pumps convince with pressure-stable and speed-proportional conveying.

Power-performer with maximum servicing convenience

The CC series®

- Easy and rapid replacement of pumping elements

- Minimal space requirement, special for service & maintenance

- Designed for heavy-duty use, suitable for pumping highly abrasive media and those with high foreign matter content

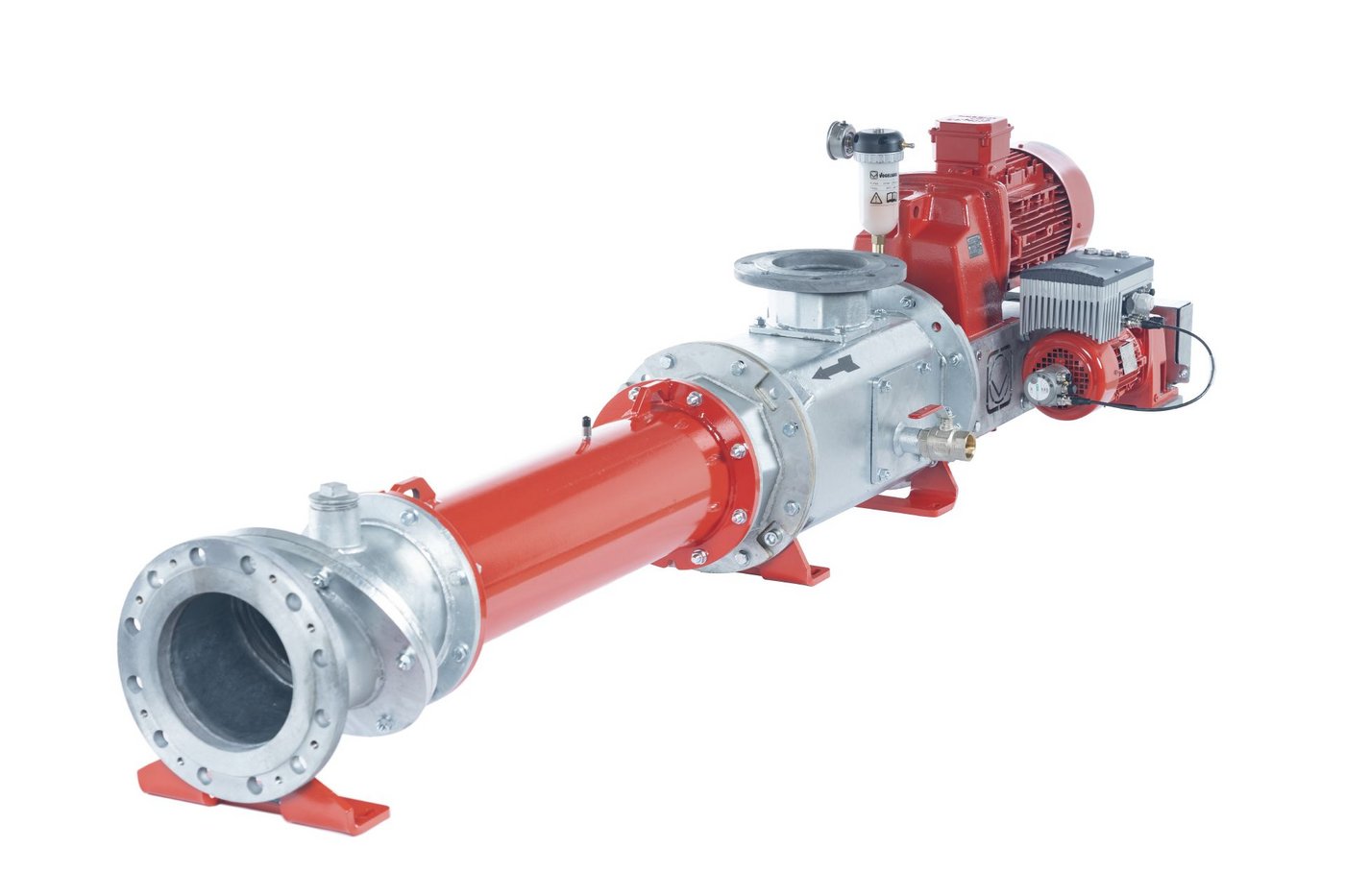

The unique progressive cavity pump with groundbreaking adjustment system

HiCone®

- Reduced lifecycle costs

- Several times longer service life

- Optimal adjustment for maximum efficiency

- Intelligent automatic start-up for minimal power consumption on start-up

- Easy to maintain and low maintenance

- Features status indicator to avoid unexpected failures

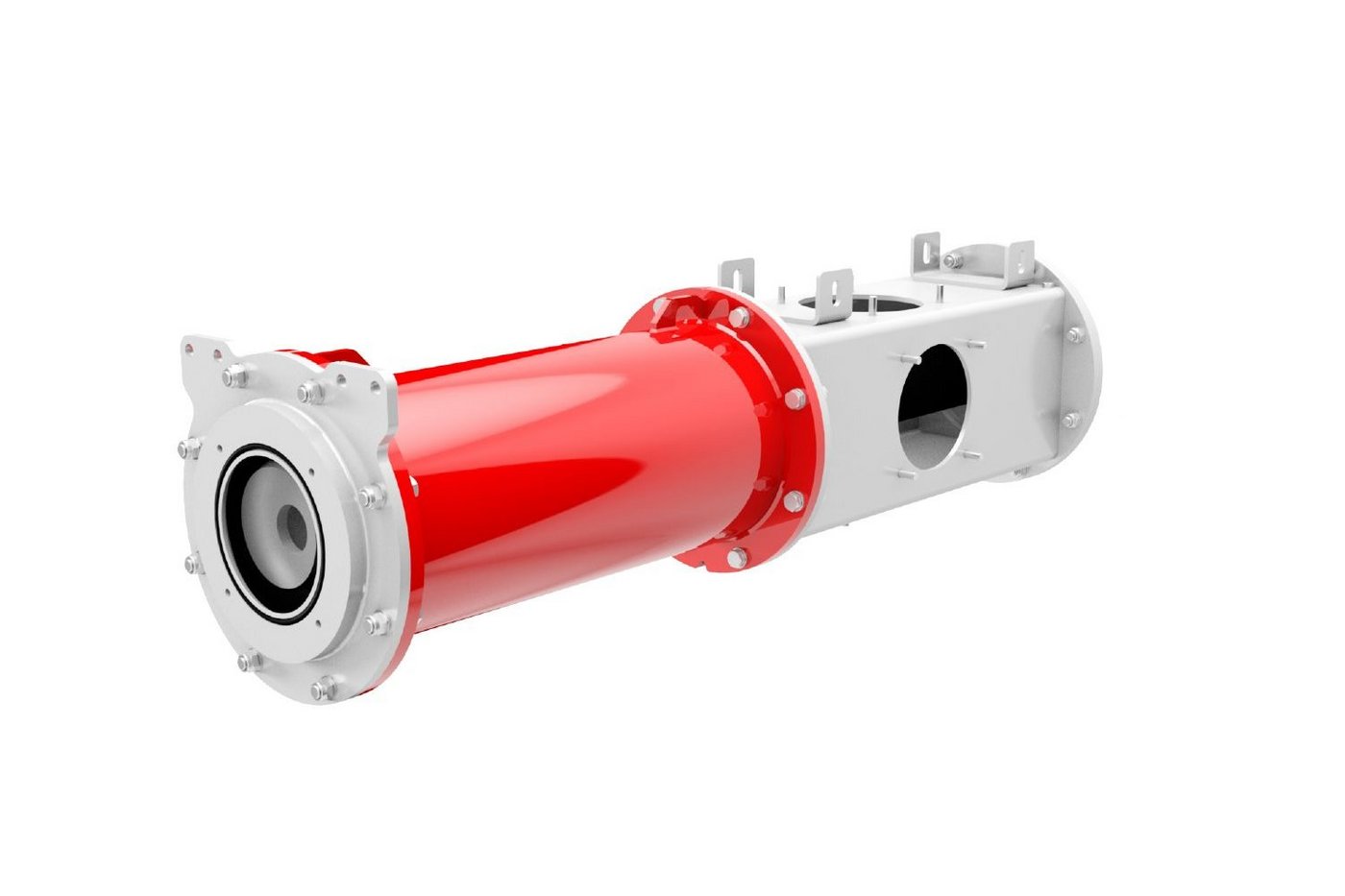

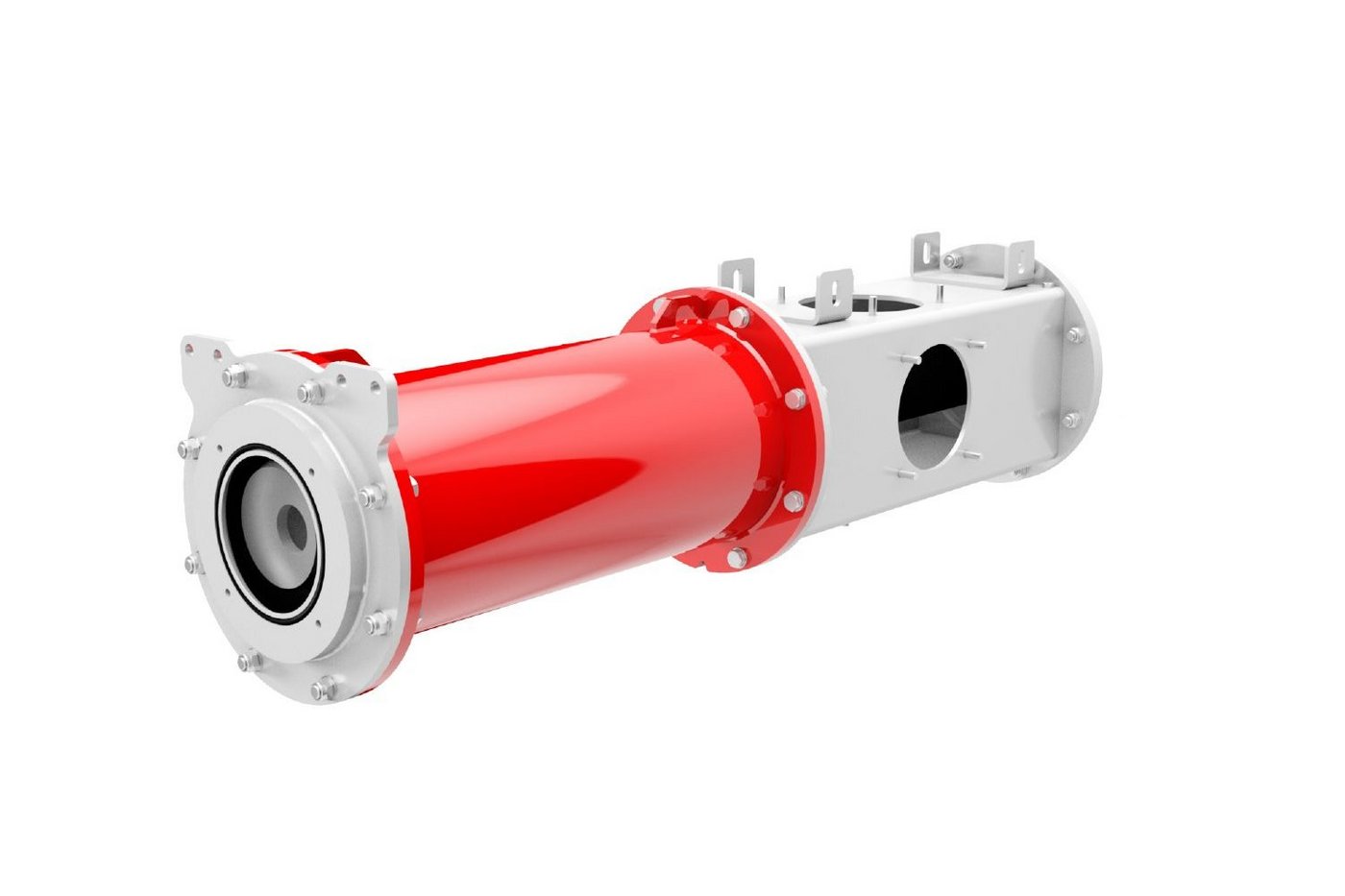

Robust pump solution with compact installation dimensions

ProCap T

- More compact installation dimensions compared to other screw pumps

- Intelligent modular system for low spare parts inventory and greater flexibility

- Fully welded housing for maximum durability

- Large free passage for maximum service life

- Low-wear pumping thanks to high resistance to foreign matter

Power-performer with maximum servicing convenience

The CC series®

- Easy and rapid replacement of pumping elements

- Minimal space requirement, special for service & maintenance

- Designed for heavy-duty use, suitable for pumping highly abrasive media and those with high foreign matter content

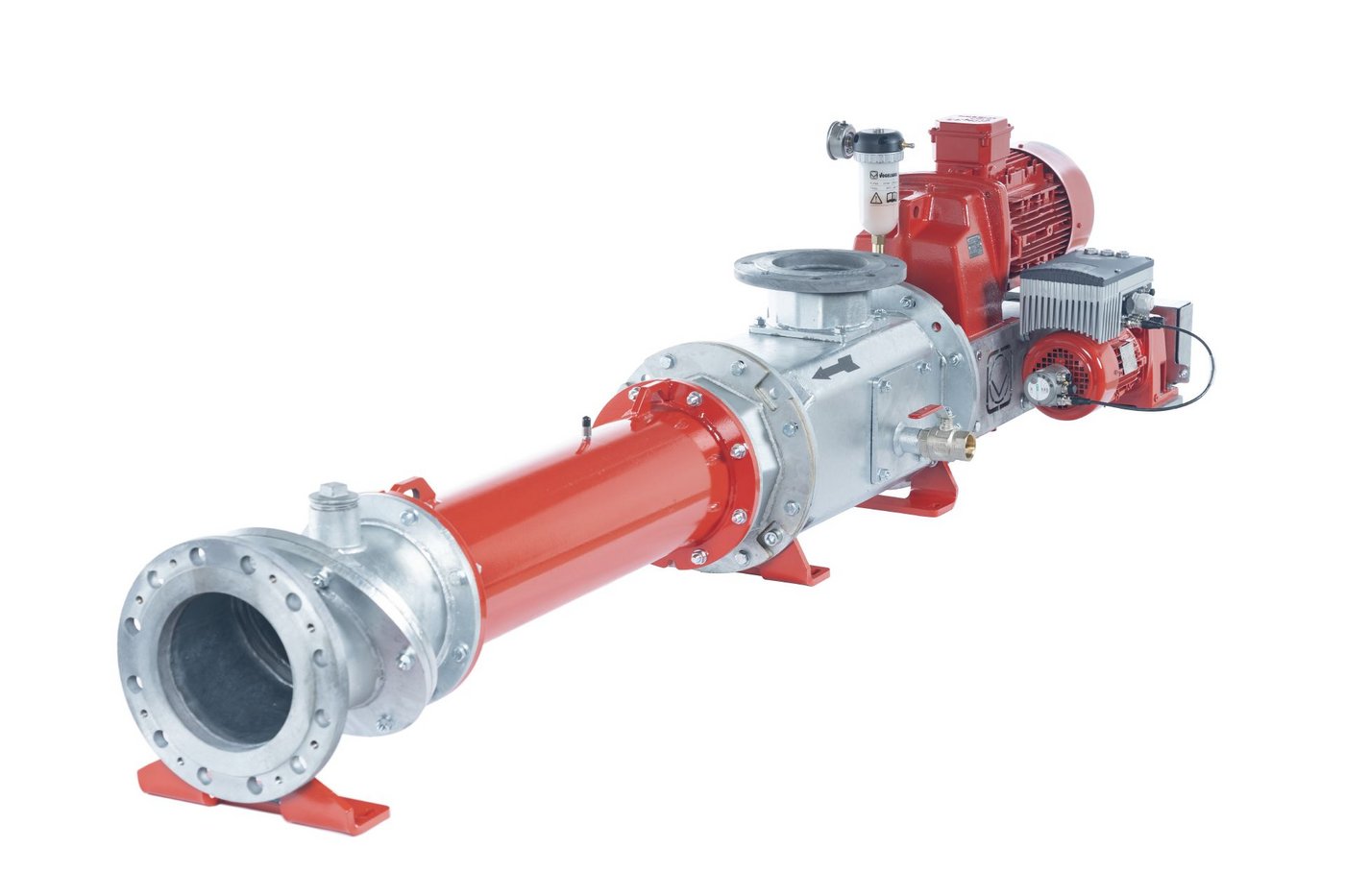

The unique progressive cavity pump with groundbreaking adjustment system

HiCone®

- Reduced lifecycle costs

- Several times longer service life

- Optimal adjustment for maximum efficiency

- Intelligent automatic start-up for minimal power consumption on start-up

- Easy to maintain and low maintenance

- Features status indicator to avoid unexpected failures

Robust pump solution with compact installation dimensions

ProCap T

- More compact installation dimensions compared to other screw pumps

- Intelligent modular system for low spare parts inventory and greater flexibility

- Fully welded housing for maximum durability

- Large free passage for maximum service life

- Low-wear pumping thanks to high resistance to foreign matter