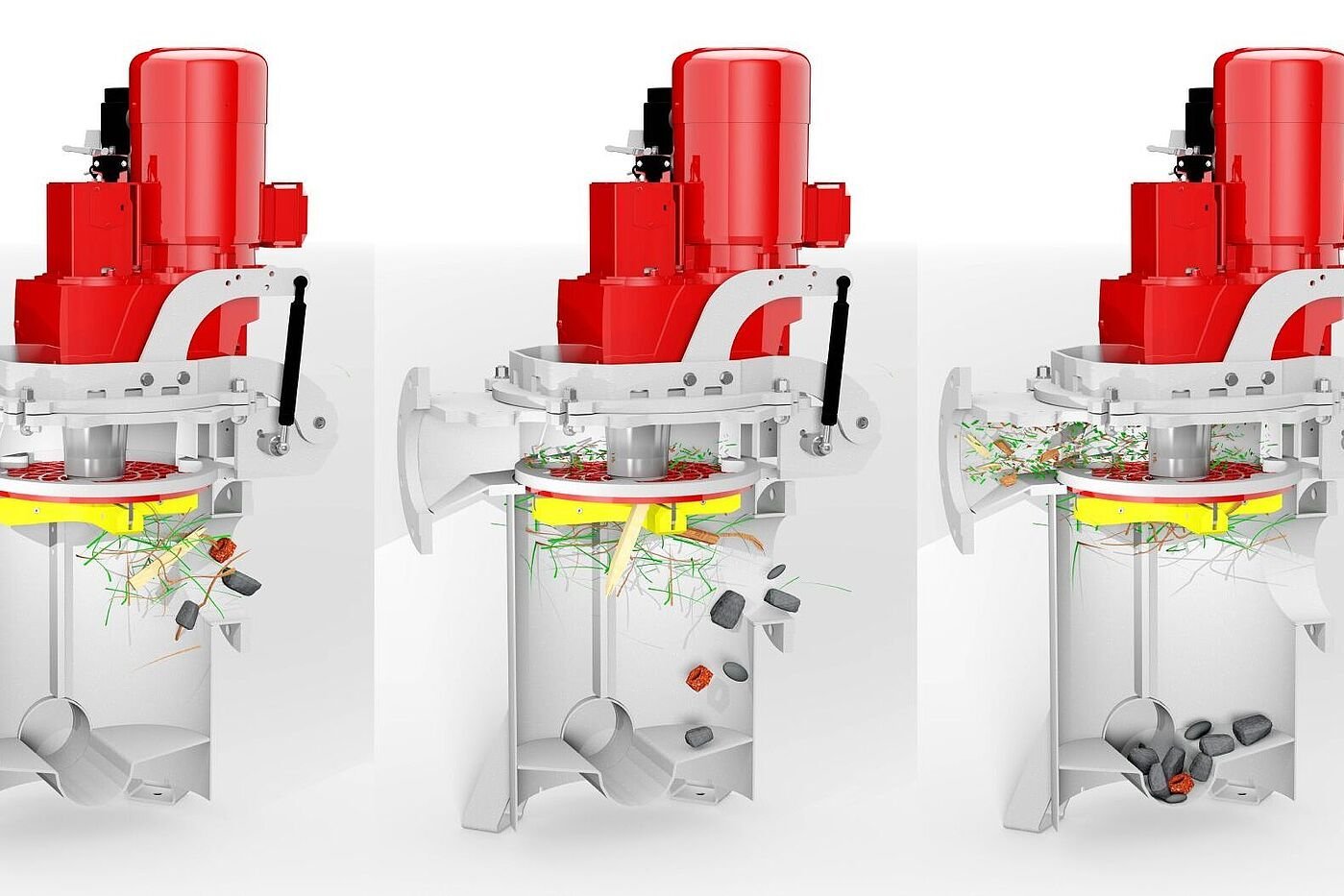

How the wet cutter RotaCut works

The operating principle

The medium flows steadily through the RotaCut. Foreign matter (stones, metal parts, etc.) is separated out based on its size or weight and can be easily disposed of later via a cleaning port. All floating and suspended substances within the medium (fibers, hair, bones, wood, etc.) are transported to the cutting screen by the liquid current and are reliably crushed by rotating, self-sharpening blades – even hair and industrial fibers are no problem. Liquids containing solid matter are transformed into pumpable, homogeneous suspensions. This makes the wet cutter RotaCut an effective tool for homogenizing heterogeneous media, such as is increasingly required in the food industry, abattoirs and biogas plants. Another important function of the RotaCut is effective heavy material separation. Stones or metal parts, etc., that cannot be chopped down are safely retained and channeled into a collecting container. The wet cutter RotaCut thereby effectively protects pumps, pipe systems and biogas plant parts from damage due to foreign matter.