The powerful pump system

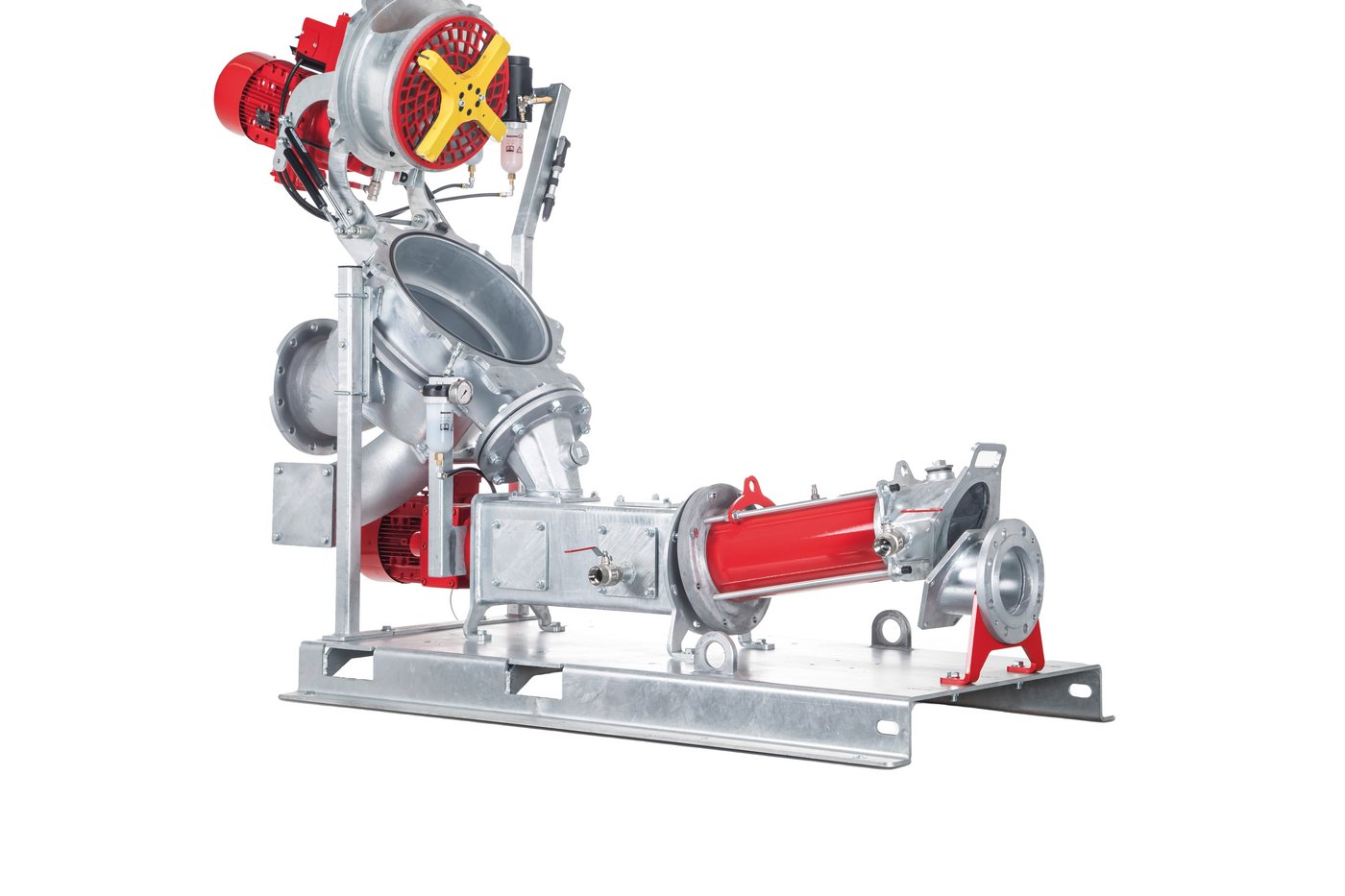

CC-Cut

- Efficient pumping thanks to optimally coordinated pump and cutter

- Reliable, trouble-free pumping of challenging and highly viscous media

- Treatment of disruptive matter and separating out of heavy material before the pump

- Low space requirements thanks to extremely compact design

- Maintenance and changing of parts can be performed quickly and easily on site

Effective combination

Developed specially for biogas plants

In most biogas plants, it’s necessary to prime, pump and prepare highly diverse liquid media. They usually contain a great deal of solids and fibrous matter, as well as disruptive matter like branches, hoof clumps, etc. – that are highly viscous and loaded with many foreign matter. Vogelsang has developed the compact pump system CC-Cut especially for these kinds of demanding pumping tasks. It comprises a robust progressive cavity pump with a powerful upstream cutter.

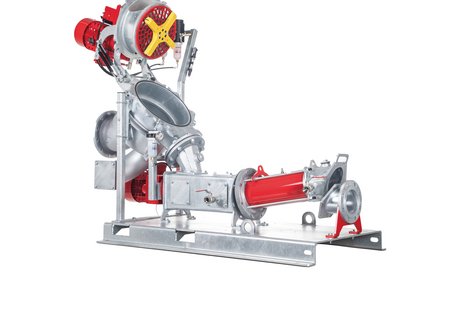

The small, maintenance-friendly pump system for low volume flows

CC-Cut / RCQ-33Gpro

Treating and pumping small volumes of viscous media, reliably protecting downstream units from foreign and disruptive matter and heavy material: The CC-Cut, based on the RCQ-33Gpro, is ideal for these tasks. With the CC-series progressive cavity pump and the RotaCut cutter from the RCQpro series, maintenance of this system couldn't be easier.

Downloads

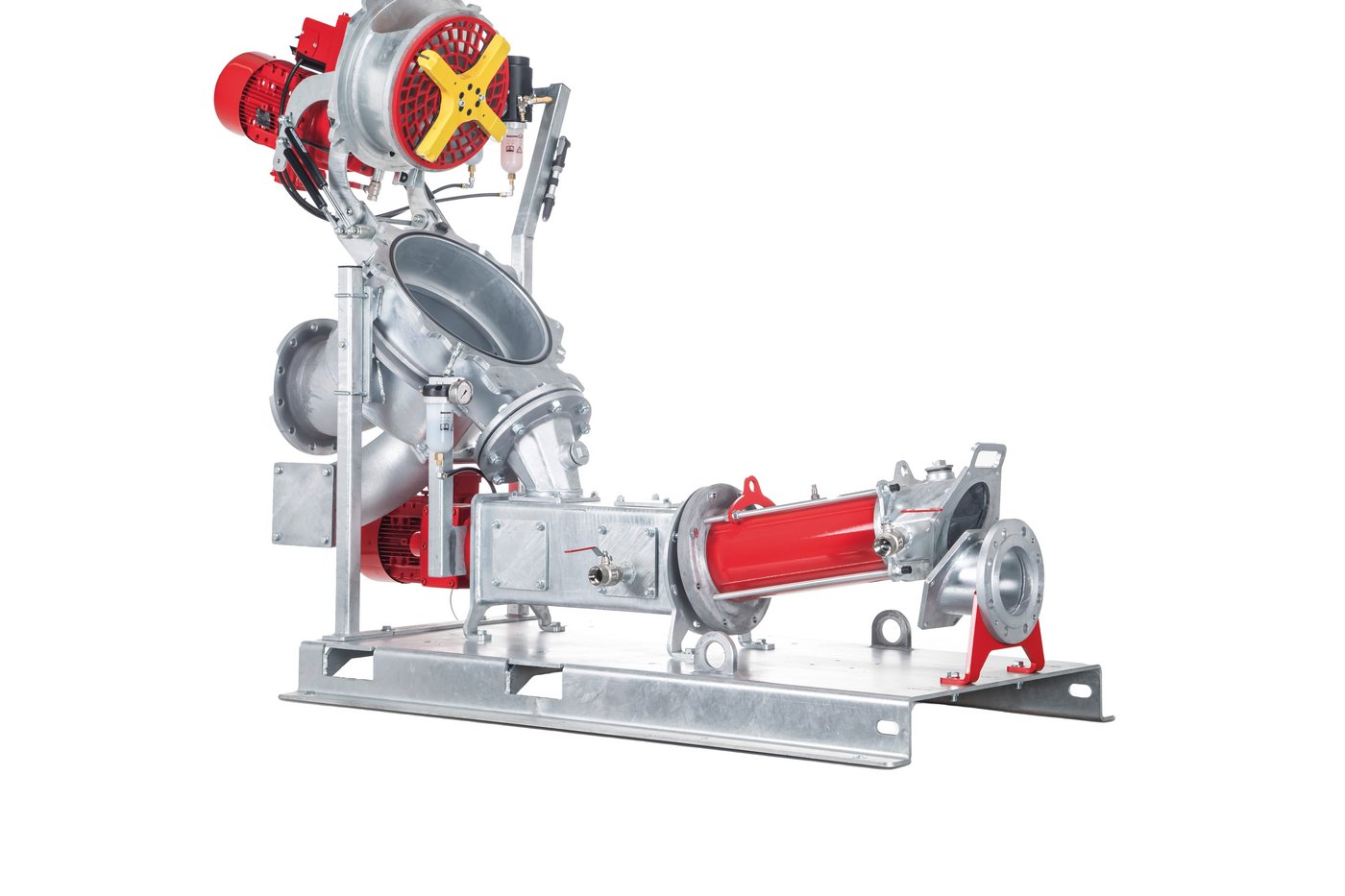

The compact, easy-to-maintain pump system for intensive preparation

CC-Cut / RCQ-43Qpro

The CC-Cut systems, based on the RotaCut RCQ-43Gpro, provide intensive preparation of viscous media, while at the same time ensuring rapid maintenance and quick and easy on-site part replacement. Disruptive and foreign matter is reliably macerated and heavy material is separated out, reliably preventing problems and malfunctions in downstream process stages.

Downloads

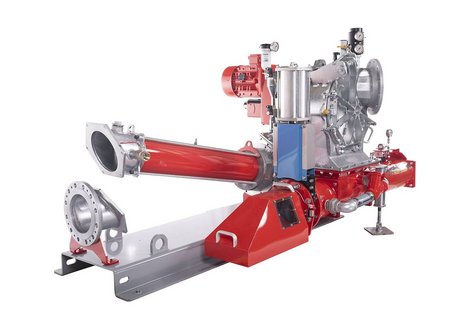

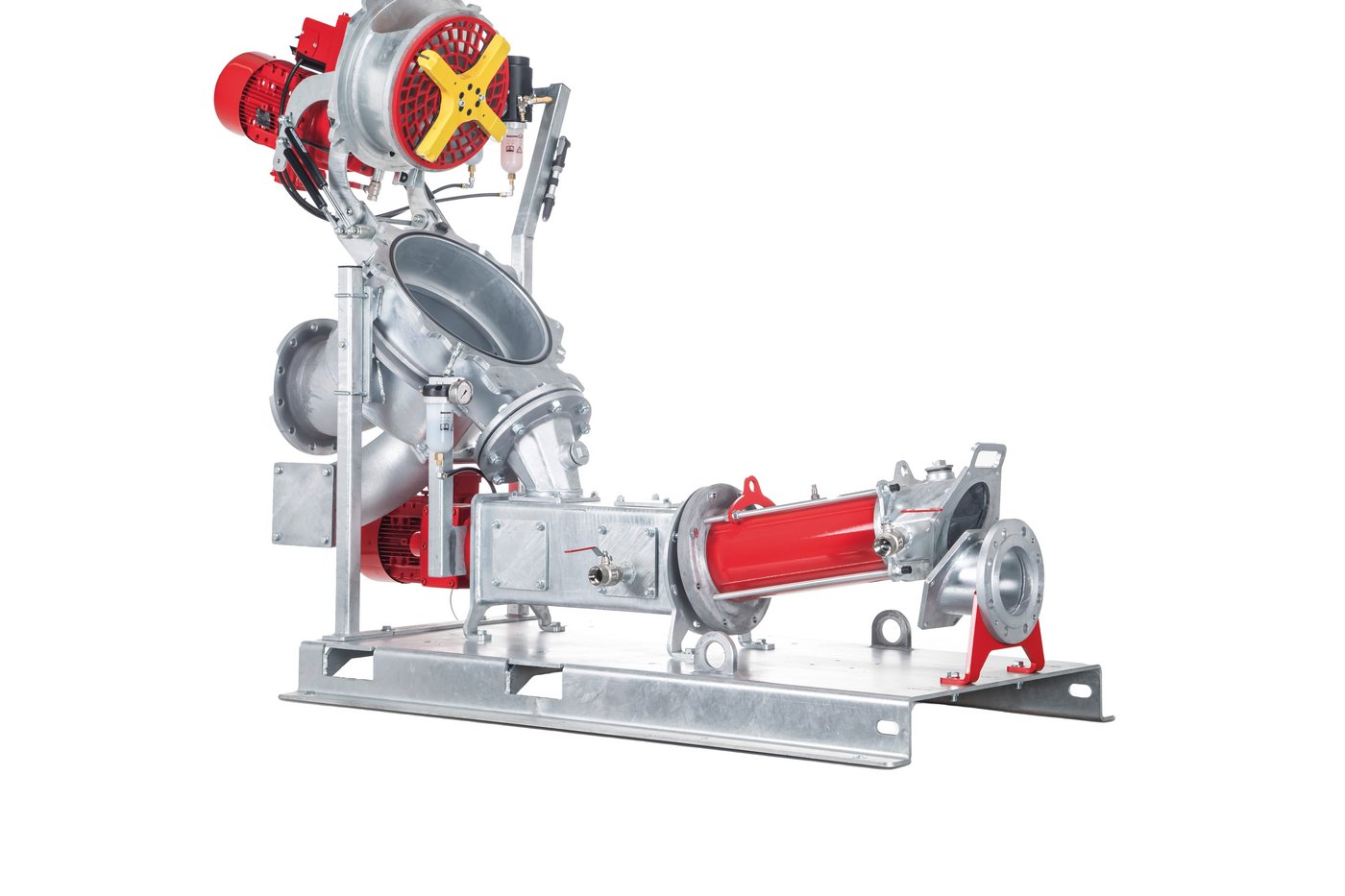

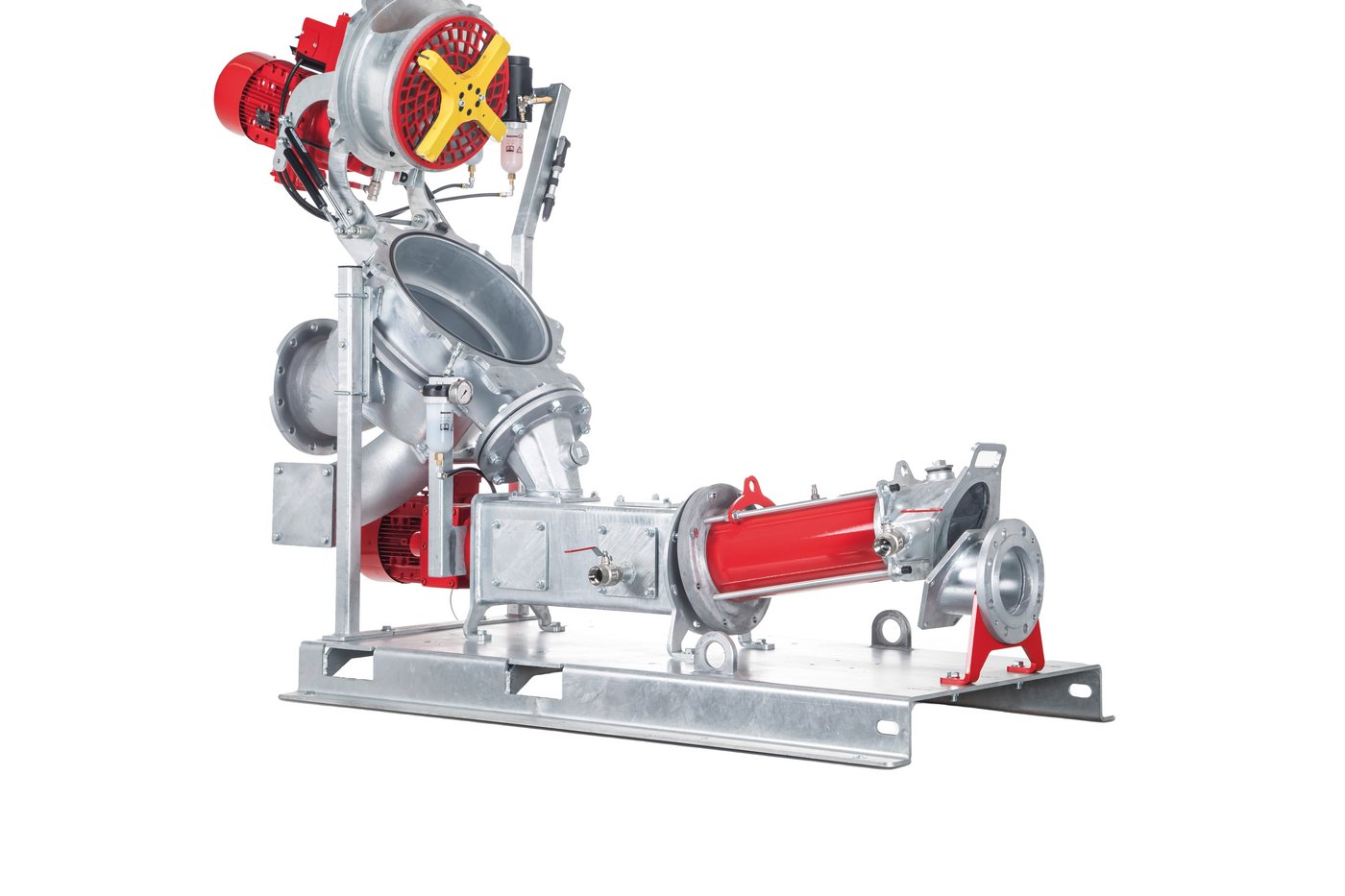

The all-purpose and efficient pump system

CC-Cut / RCX-48G

For economical preparation of large-volume flows of many kinds of different media, of high and medium viscosity. The combination of a CC-series progressive cavity pump and the RotaCut RCX-48G guarantees a long service life and efficient reduction of solid and disruptive matter as well as reliable separation of heavy matter, while at the same time being easy to use and to maintain.

Downloads

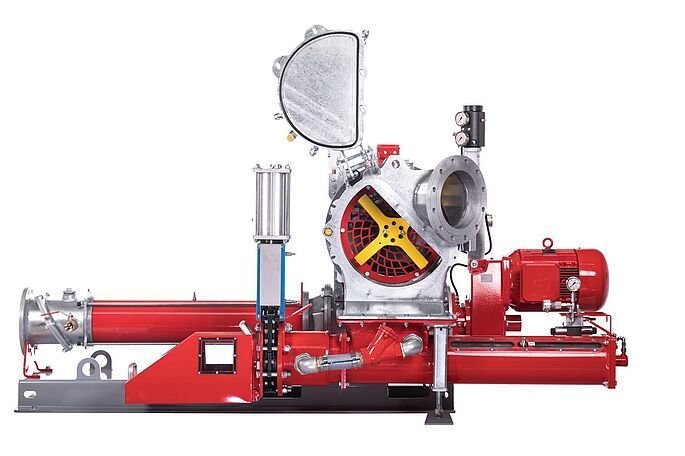

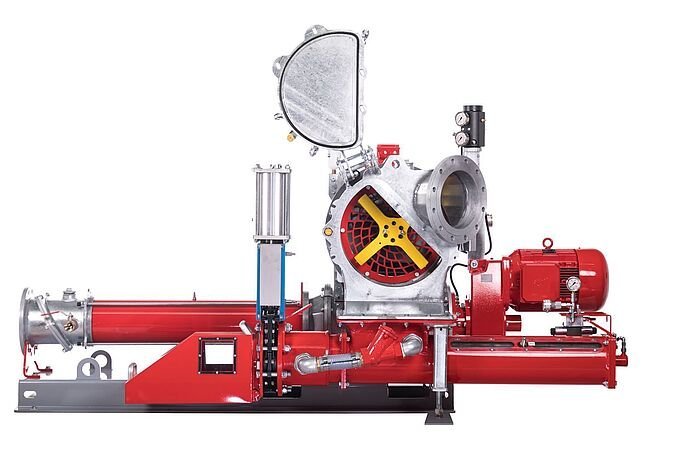

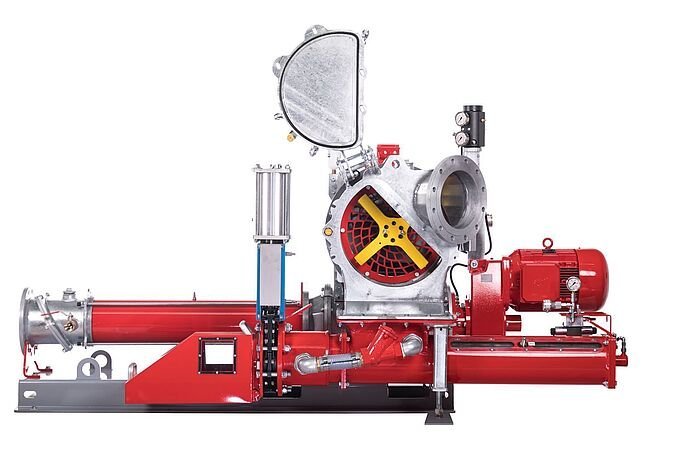

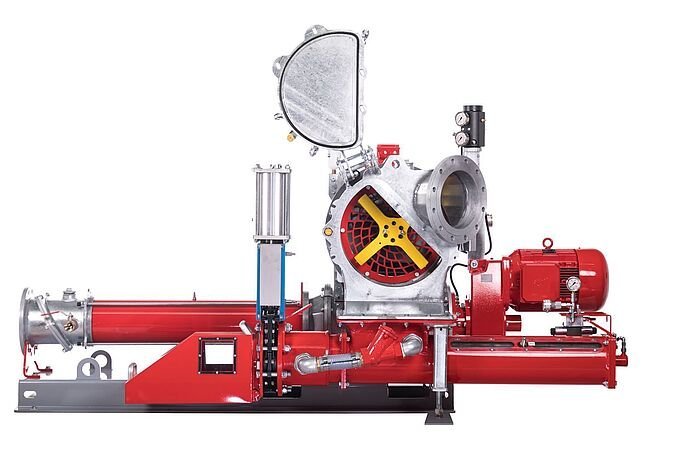

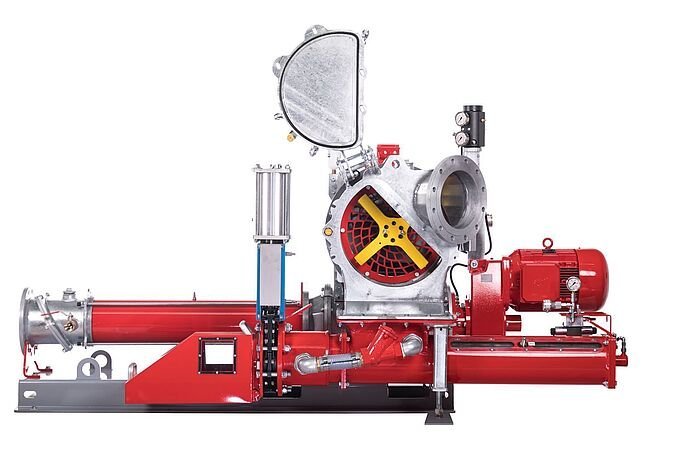

The highly effective and powerful pump system for intensive preparation

CC-Cut / RCX-58G

The efficient solution for pumping large-volume flows of viscous and highly viscous suspensions and media, with intensive preparation beforehand. The RotaCut RCX-58G reliably separates out heavy material, macerates disruptive and solid matter dependably, and homogenizes the medium at the same time. This prevents malfunctions and disruptions in downstream units and components, and forms the basis for efficient processes.

Downloads

The small, maintenance-friendly pump system for low volume flows

CC-Cut / RCQ-33Gpro

Treating and pumping small volumes of viscous media, reliably protecting downstream units from foreign and disruptive matter and heavy material: The CC-Cut, based on the RCQ-33Gpro, is ideal for these tasks. With the CC-series progressive cavity pump and the RotaCut cutter from the RCQpro series, maintenance of this system couldn't be easier.

Downloads

The compact, easy-to-maintain pump system for intensive preparation

CC-Cut / RCQ-43Qpro

The CC-Cut systems, based on the RotaCut RCQ-43Gpro, provide intensive preparation of viscous media, while at the same time ensuring rapid maintenance and quick and easy on-site part replacement. Disruptive and foreign matter is reliably macerated and heavy material is separated out, reliably preventing problems and malfunctions in downstream process stages.

Downloads

The all-purpose and efficient pump system

CC-Cut / RCX-48G

For economical preparation of large-volume flows of many kinds of different media, of high and medium viscosity. The combination of a CC-series progressive cavity pump and the RotaCut RCX-48G guarantees a long service life and efficient reduction of solid and disruptive matter as well as reliable separation of heavy matter, while at the same time being easy to use and to maintain.

Downloads

The highly effective and powerful pump system for intensive preparation

CC-Cut / RCX-58G

The efficient solution for pumping large-volume flows of viscous and highly viscous suspensions and media, with intensive preparation beforehand. The RotaCut RCX-58G reliably separates out heavy material, macerates disruptive and solid matter dependably, and homogenizes the medium at the same time. This prevents malfunctions and disruptions in downstream units and components, and forms the basis for efficient processes.

Downloads

Features of the CC-Cut

Options of the CC-Cut

Power for your biogas plant with the pump system CC-Cut

The pump system CC-Cut for biogas applications

Pumping liquid manure, recirculate and organic suspensions is part of the daily work at many biogas plants. However, these media often contain long-fibred solid matter (straw, grass, feed residue), heavy material (metal parts, stones) or disruptive matter (ear tags, branches etc.). This content has a negative impact on the ability to pump the medium, results in increased power consumption of pumps and mixers, and causes malfunctions or even damage, thereby decreasing the cost-effectiveness of a biogas plant.

Vogelsang developed the pump system CC-Cut precisely for these applications. It combines a progressive cavity pump from the CC series with a RotaCut in a compact design. This means that the CC-Cut can be integrated into most biogas plants as the central pump system, without taking up much space. And the CC-Cut also reliably separates heavy material out of highly viscous media, reduces disruptive matter to a manageable size, cuts solid matter and mixes everything intensively.

The optimally treated medium is then pumped reliably and trouble-free even against high pressures. In addition, the efficient treatment also reduces the viscosity and the tendency to form floating layers. Both are positively noticeable through a lower energy requirement.

Maintenance and replacing parts are quick and easy with the pump system CC-Cut as they are for the individual components because both retain the full service function: all wear parts can be replaced on site.

Downloads