Cost effective slurry separation

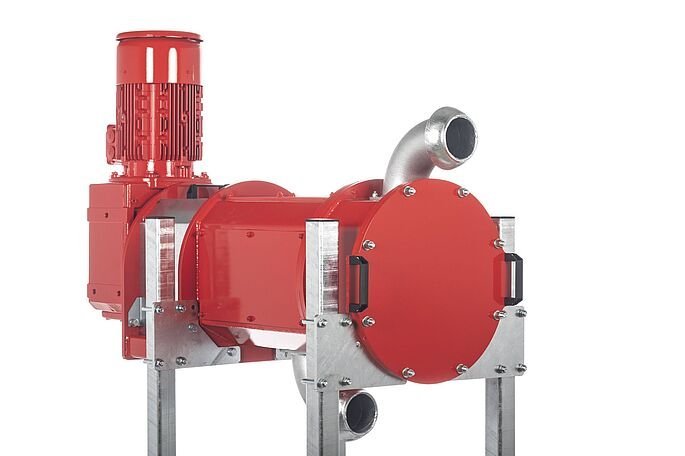

XSplit®

- High Efficiency: Up to 40% dry matter and 50m³/h throughput

- Increased Storage: Up to 20% extra slurry storage capacity

- Easy Adjustments: Adaptable pressing area to dry matter

- High Performance: Reliable plug formation without additional tools

- Improved Nutrients: Enhanced nutrient uptake and reduced mycotoxin risk

- User Friendly: Low-maintenance, cost-effective design

Efficient separation of solid and slurry

The XSplit® slurry separator: cost effective and user friendly design

Vogelsang refined the press screw separator design to boost efficiency, maximise nutrient recovery, and reduce energy use. Positioning the drive at the solid matter outlet ensures uniform plug formation for better performance and user experience.

Separating digestate or slurry improves slurry management by minimising floating and sinking layers in the silo. The solid fraction is easier to transport and can be repurposed as animal bedding or a peat substitute. Meanwhile, the thin liquid phase spreads more easily and evenly, enhancing nutrient uptake—especially in wet conditions—or reducing digester viscosity.

See the XSplit in action in our video here on YouTube.

Models of the XSplit®

Superior separation process

Vogelsang reengineered the proven press screw separator concept to create the XSplit, delivering an excellent cost-benefit ratio. With high throughput rates of up to 50 m³/h and an easily adjustable dry matter content of up to 40%, it outperforms other press screw separators on the market.

The XSplit features a segmented sieve basket, allowing individual sieve elements to be replaced without overhauling the entire basket—extending service life and minimising downtime. Maintenance is simplified with an easily removable end cover, providing direct access to the sieve basket and press screw. Designed for versatility, our XSplit options offer slurry separation solutions for both mobile and standalone setups to suit your needs.

Superior separation process

Vogelsang reengineered the proven press screw separator concept to create the XSplit, delivering an excellent cost-benefit ratio. With high throughput rates of up to 50 m³/h and an easily adjustable dry matter content of up to 40%, it outperforms other press screw separators on the market.

The XSplit features a segmented sieve basket, allowing individual sieve elements to be replaced without overhauling the entire basket—extending service life and minimising downtime. Maintenance is simplified with an easily removable end cover, providing direct access to the sieve basket and press screw. Designed for versatility, our XSplit options offer slurry separation solutions for both mobile and standalone setups to suit your needs.