Technology for sewerage and pump stations

Pumping and macerating technology for reliable and trouble-free operation

Efficient and reliable wastewater systems depend on advanced pump and grinder technology to ensure smooth daily operation. From sewer networks to pumping stations, these technologies play a vital role in keeping everything running smoothly, preventing blockages and allowing wastewater to flow freely. In this context, innovative pump designs and robust grinders are essential components that ensure minimal downtime, optimal performance and cost-effective maintenance. Vogelsang technology helps you to keep your wastewater systems running without interruption.

Our standard: Cutting-edge and efficient sewage pumps

Reliable and trouble-free wastewater and sewage pumping is particularly important in the sewer system. The sewers and pipes must be sufficiently dimensioned for heavy rainfall events, just as minimal amounts of water should not lead to deposits and unpleasant odors during dry periods. In addition, there is often little space available for installation. This raises the following questions for the user: Which lifting units require little space? Can or should sewage pumps be installed dry, for example to avoid an Atex design in wet areas or to simplify servicing and maintenance? If so, this usually means that the sewage pump must be able to prime and be insensitive to dry running. Vogelsang rotary lobe pumps from the VX series and IQ series are ideally suited as waste water pumps. They are compact, can be installed even in the smallest of spaces and require extremely little space in the so-called semi-mounted design. They can be maintained or repaired quickly and easily on site without having to be removed. They also easily meet the increasing demand for high delivery heads and high pressures in order to overcome the longer distances to large central sewage treatment plants. They can also draw in waste water from deep shafts, as they are characterized by their high resistance to dry running.

Grinding of foreign matter in wastewater

Time and time again, municipal sewage or commercial and industrial sewage contains foreign matter that has no business being there. This enters the sewage system in various ways, where it causes considerable problems. Sewage network operators are therefore on the lookout for technical solutions that can handle foreign matter. Wastewater grinders like the XRipper twin-shaft grinder or the RotaCut macerator with integrated heavy material separators win customers over due to their many qualities and features.

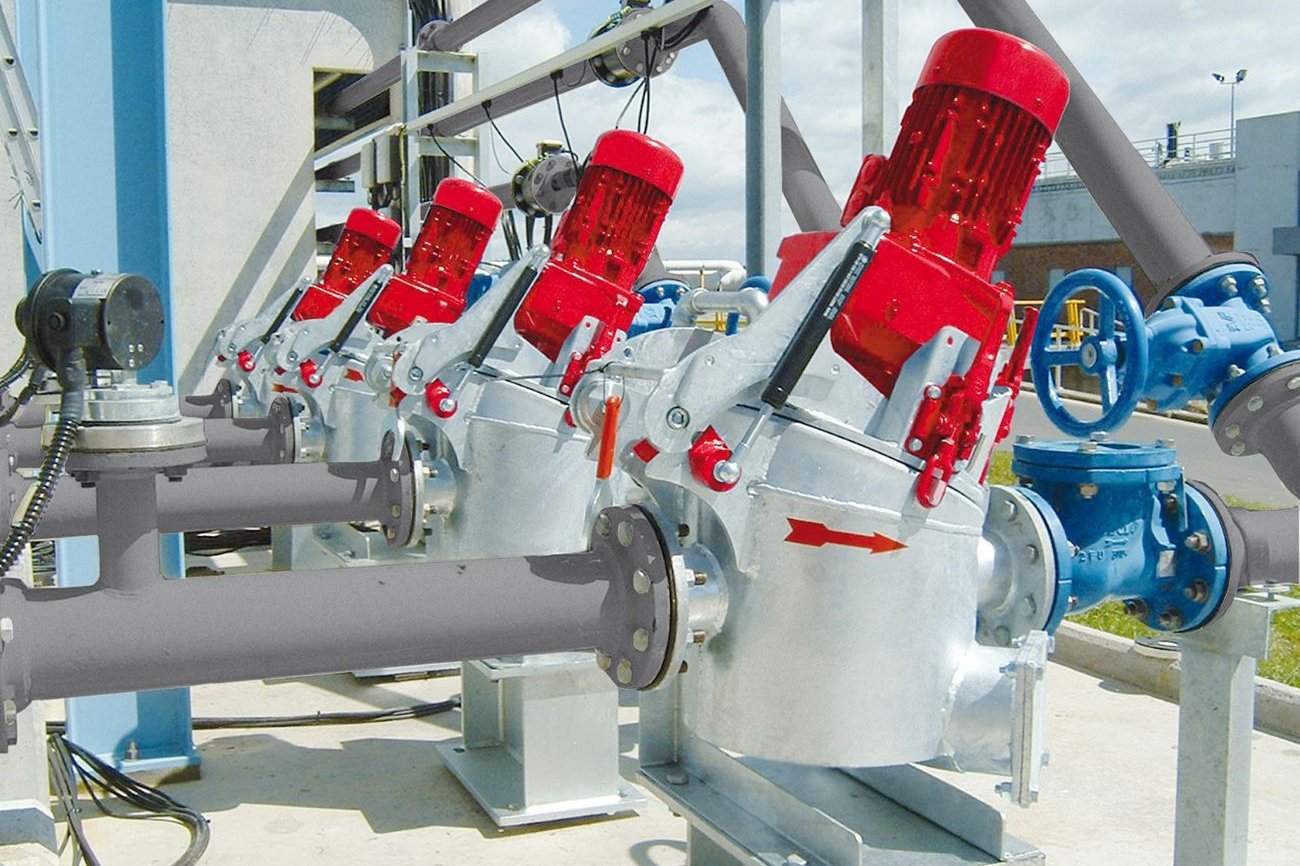

The XRipper wastewater grinders reduces foreign matter contained in wastewater like wet wipes and textiles to unproblematic sizes. These solids are then so small they no longer cause clogging or blockages in downstream wastewater pumps and fittings but are large enough for them to be filtered reliably from the wastewater by the screen of the wastewater treatment plant. The contactless principle of operation is important for low-wearing operation here while the range of installation options also plays an important role. Wastewater grinders can be installed in three ways:

- In the classic, highly easy-to-maintain design with geared motor for installation in pipeline networks

- In a vertical arrangement with the motor arranged above the XRipper where space is at a premium

- With open housing for use in sewers or for installation directly in front of inlets, sewage treatment plant outlets, collection sumps and pump sumps

With all three designs, operating companies also profit from our unique QuickService concept where all wastewater grinders are low maintenance and can be repaired or serviced on site quickly and simply.

Highly compact heavy material separation and maceration

Another essential function that is often found in sewage systems is the separation of heavy material like stones and metal parts as well as the macerating of foreign matter like waste and wood. In older open sluices for instance, an adequate screen and/or foreign matter separator is often lacking in front of the wastewater pump. Due to upgrades, partial upgrades, and the considerable variations in regional developments, each application is often very different from the other so that individual solutions are required for the relevant volume flow, available space or the maximum electrical power available. The RotaCut macerator by Vogelsang comes in an extensive range of models with numerous features and options, and reliably separates heavy material, macerates floatable disruptive matter and even shreds stubborn foreign matter like coarse pieces of wood using the AutoReverse function. Thanks to the sophisticated control technology, the wastewater macerator can be connected to remote maintenance and operating parameters are displayed online.