The economical liquid feeding system for solid matter incorporation

CC-Mix

- Mashes simple biomass cost-effectively to form a homogeneous organic suspension

- An integrated foreign matter separator removes heavy material before it can reach the pump unit

- Is uncomplicated to integrate thanks to its compact dimensions and simple control

- Several digesters can be fed from one CC-Mix

- Easy to change parts on site

Liquid feeding from an economic perspective

The CC-Mix for digester feeding with flowable to slightly pasty solid matter

Unproblematic, energy-rich cosubstrates are desirable and valuable. As a result, it is extremely important for efficient biogas production to feed solid matter like maize silage, dry chicken manure, sugar beet pulp, grain meal or fruit and vegetable waste with less effort, yet optimal prepared. A reliable, energy-efficient mashing process helps maximize the use of the nutrients contained in the valuable cosubstrates.

Performance : The CC-Mix strenghts deliver it: Thanks to its thought-out engineered design, it requires minimum power to mash the cosubstrates with the liquid to form a homogeneous suspension, thus providing the conditions necessary for optimum fermentation in the digester.

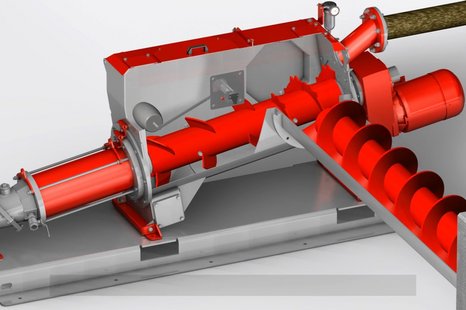

Design and operating principle: The CC-Mix brings together proven components into a new design. It is based on the unique, easy-to-maintain progressive cavity pump from the CC series (Cavity-Comfort), supplemented by a generously sized mixing chamber. The solid matter is transported into the mixing chamber via a feed screw at the side or from above. At the same time, liquid, such as recirculated material, is added at the beginning of the mixing chamber.

Maintenance and repairs: Parts replacement is quick and easy, thanks to the innovative QuickService concept of the CC series: The rotor and stator swivel out as a unit for quick-and-easy removal and replacement. If necessary, the mixing shaft can also be replaced with just a few manual steps. Downtimes in the feeding process due to service and maintenance are reduced to a minimum.

Models of the CC-Mix

The standard version of the cost-effective liquid feeding system

CC-Mix66-M1

The CC-Mix66-M1 is the standard version of the CC-Mix for the cost-effective digester feed with flowable to slightly pasty solids. With a capacity of up to 50 m3/h and pressures of up to 6 bar, it is just the right choice for many typical biogas systems.

Downloads

The cost-effective and powerful liquid feeding system

CC-Mix66-D1

The CC-Mix66-D1 is the powerful version of the CC-Mix for the cost-effective digester feeder with flowable to slightly pasty solids. With capacities of up to 85 m3/h and pressures of up to 6 bar, it is the right choice for large biogas systems and for everywhere where high material flow rates are required.

Downloads

Cost-effective liquid feeding system at high pressure

CC-Mix66-M2

The CC-Mix66-M2 is the two-stage version of the CC-Mix for the cost-effective digester feed with flowable to slightly pasty solids. With capacities of up to 50 m³/h and pressures of up to 12 bar, it is the right choice for biogas systems if higher pressures are required.

Downloads

The standard version of the cost-effective liquid feeding system

CC-Mix66-M1

The CC-Mix66-M1 is the standard version of the CC-Mix for the cost-effective digester feed with flowable to slightly pasty solids. With a capacity of up to 50 m3/h and pressures of up to 6 bar, it is just the right choice for many typical biogas systems.

Downloads

The cost-effective and powerful liquid feeding system

CC-Mix66-D1

The CC-Mix66-D1 is the powerful version of the CC-Mix for the cost-effective digester feeder with flowable to slightly pasty solids. With capacities of up to 85 m3/h and pressures of up to 6 bar, it is the right choice for large biogas systems and for everywhere where high material flow rates are required.

Downloads

Cost-effective liquid feeding system at high pressure

CC-Mix66-M2

The CC-Mix66-M2 is the two-stage version of the CC-Mix for the cost-effective digester feed with flowable to slightly pasty solids. With capacities of up to 50 m³/h and pressures of up to 12 bar, it is the right choice for biogas systems if higher pressures are required.

Downloads

Features of the CC-Mix

Options of the CC-Mix

The energy efficient solid matter feeder for cost-effective digester feeding

Liquid feeding system CC-Mix for biogas applications

Unproblematic, energy-rich biomass is desirable and valuable. For efficient biogas production, it is especially important to feed them in with a minimum of effort but with the best possible preparation. The CC-Mix excels at doing exactly that. Thanks to its carefully thought out concept, solid matter is mixed with the liquid suspension to form a homogeneous suspension, with minimal power requirements. The CC-Mix thus provides the conditions which are necessary for optimum fermentation in the digester.

This makes the CC-Mix to a cost-effective solid matter feeder for renewable resources and solid matter which can flow (such as maize silage and grain waste) through to other, slightly pasty input materials such as fruit and vegetable waste, sugar beet pulp or dry chicken manure. These get into the CC-Mix via a screw conveyor whose mixing chamber and mixing shaft are made of corrosion resistant stainless steel.

Thanks to the new design, a power of only 11-15 kW is needed to create an ideally mashed organic suspension suitable for bacteria. The integrated foreign matter separator keeps heavy material back, avoiding damage by foreign matter. As the biomass is provided in a pumpable form, it is no problem to feed several digesters from one CC-Mix.

Its installation and integration is uncomplicated both in new as well as in existing systems. Owing to its compact construction, only a few square meters are required to erect the CC-Mix - including space for service and maintenance work. In connection with a PCU control unit from Vogelsang, all of the components, including the sensors and safety components, are available to automate the solid matter feeder.

Downloads