Vogelsang Slurry Macerators

Vogelsang macerators for even and reliable slurry spreading

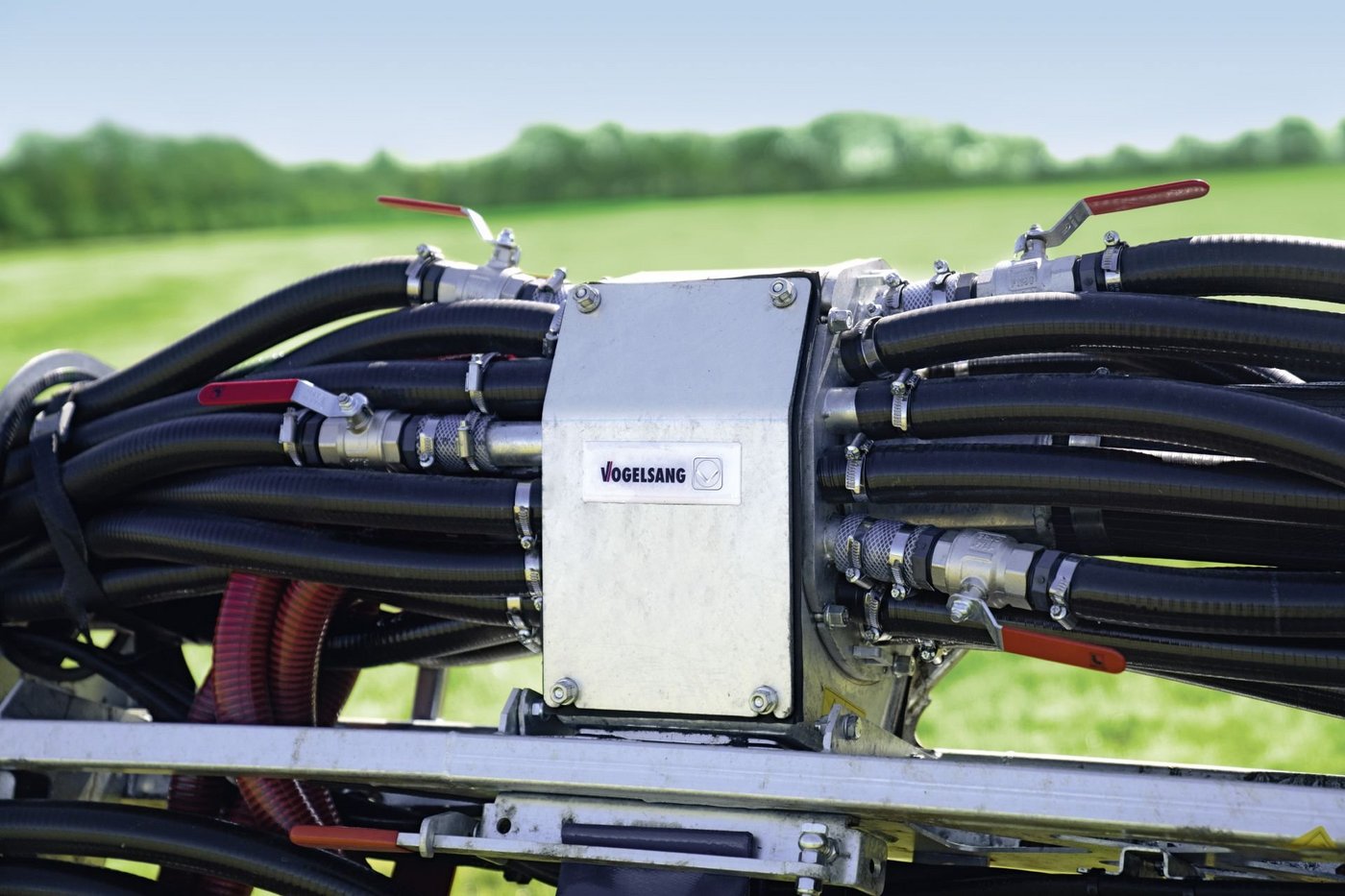

Farmers and contractors in Ireland need reliable and efficient technology for low emission slurry spreading. Vogelsang is a top manufacturer of spreading technology and invented the first macerator, which is the core of spreading systems. Our macerator models have been tested and relied in Ireland and across the world to ensure slurry is distributed evenly to all hosepipes, even with large applicators like the 36-metre Vogelsang SwingMax.

Vogelsang macerators provide the most even distribution of nutrients in slurry, with less than 5% variation. This reliability comes from the smart, robust design and top-quality components. Because slurry conditions in Ireland can be challenging with tough fibres, Vogelsang macerators are specifically designed to handle these conditions effectively. Using Vogelsang macerators not only saves on fertiliser costs but also lasts longer, making them a cost-effective investment for farms.

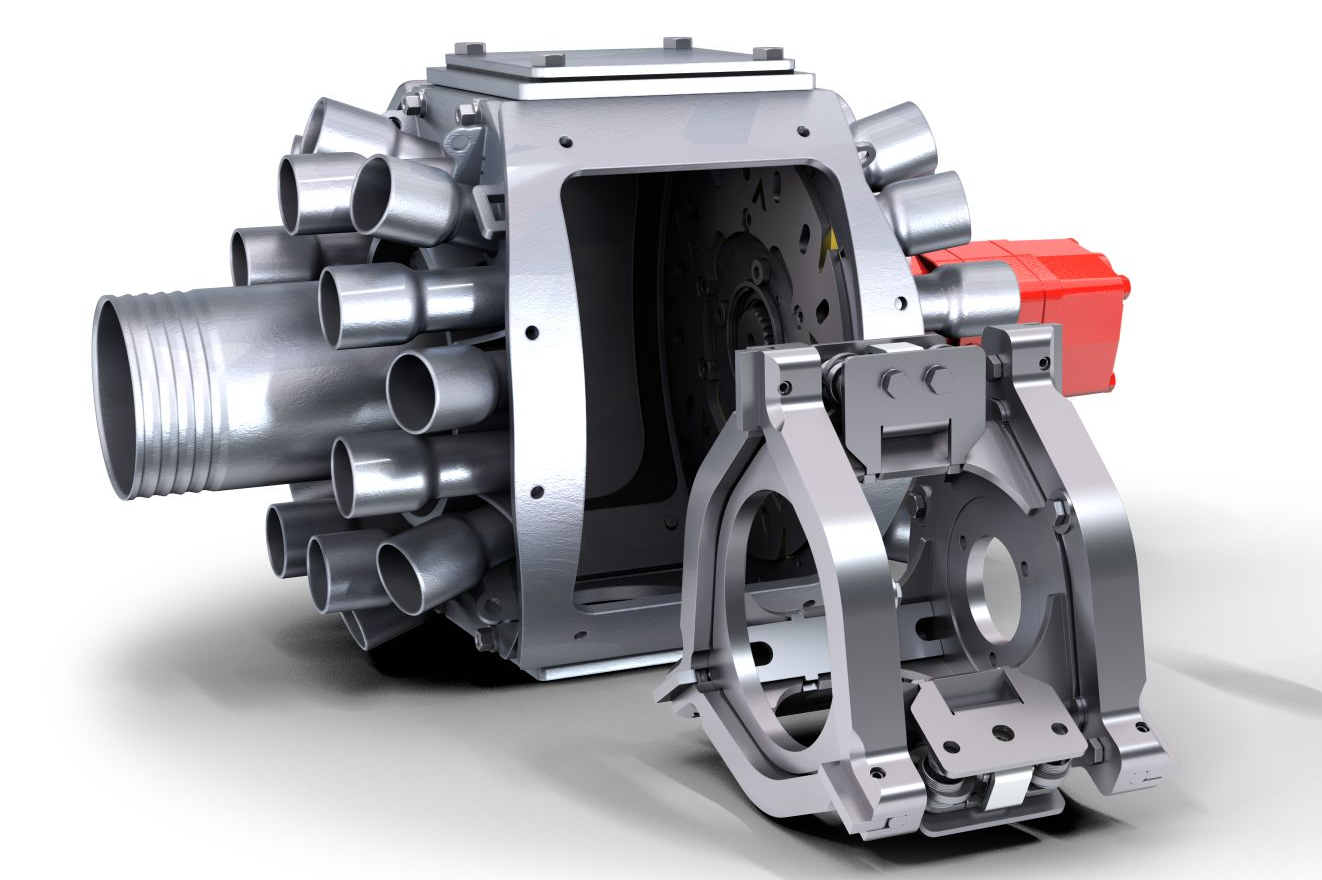

Efficient horizontal slurry distribution with variable spreading rate

DosiMat DMX

- Best distribution accuracy thanks to the flow-optimised rotor contour for use in the field of injection technology

- Consistently high distribution accuracy regardless of the flow rate

- Long service life of the cutting tools of up to 200,000 m3 per macerator

- Service friendly design for easy maintenance of all components

- Advanced cutting blade contour for reliable shredding and flow of slurry

- Air suction: Patented membrane for automatic regulation of air flow

- Reduced weight of up to 25% through selection of materials

- Maximum operational safety with sealing package between the housing and the hydraulic motor

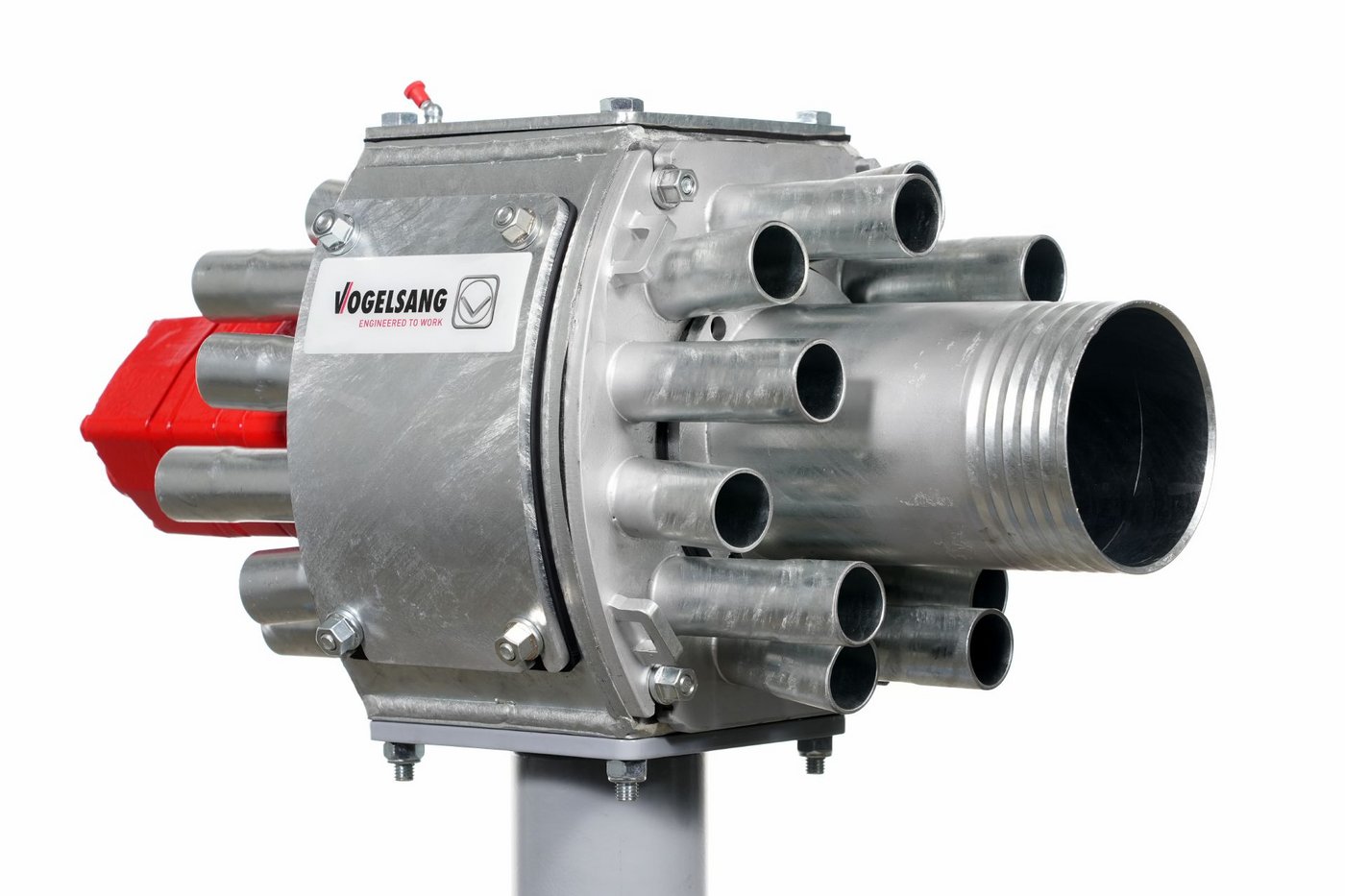

The slurry macerator without air suction

ExaCut ECC

- Innovative Air-Free Design: No need for ventilation hoses and air suction, preventing negative pressure and ensuring smoother slurry distribution

- Designed for Tough Conditions: Engineered and tested cutting principle for Ireland to withstand demanding slurry environments

- Proven maintenance concept: Easy and unique rotor maintenance in less than 20 minutes without removing a single hose

- Very smooth slurry distribution without pulsation of the hoses

- Developed for the use of injection machines and cultivators

- Cross-sections up to 150 DN for maximum effectiveness and user-friendly eccentric activation

- Efficient and Low-Cost Operation: Reduced power and oil requirements while maintaining optimal performance - only 35 l oil capacity

The classic Vogelsang macerator with optimal cutting results and reliability

ExaCut ECL

- Proven 10,000 times over making it the best-selling macerator in the world

- Tried and tested in demanding slurry environments in Ireland over 15 years

- Vertical rotor with self-sharpening cutting blades, macerates, separates, and distributes slurry in one step

- Easy maintenance: Quick part changes without disassembly

- Robust and compact design with high-quality materials to handle local slurry conditions

- Optimal hydraulic drive motor running around 35L/min

- Self-sharpening cutting tools: Reversing the rotation direction maintains a constant degree of sharpness over the entire lifetime

- Sealing package between the housing and the hydraulic motor for maximum operational safety

- Excellent distribution accuracy and maceration

Macerator without air suction in a compact space

ExaCut ECM

- Precise slurry distribution without aeration hoses and air suction

- Innovative rotor concept with high cutting power

- Our smallest and most compact macerator

- 30 % less weight due to space-saving housing

- Universally applicable and east to retrofit even with short hose paths

- Very good transverse slurry distribution already at 1500 l / min per macerator

- Continuous optimum degree of cutting knives sharpness due to change of direction of rotation

- Conical screens for optimum cutting results

Heavy Duty design with the best distribution accuracy

ExaCut ECQ

- Designed to handle tough fibre slurry conditions in Ireland

- Achieving 99% accuracy in slurry distribution to all hosepipes making it the most even and consistent distribution

- Easiest maintenance available on the market with convenient access to parts, ensuring fast servicing

- Long life of wearing parts with 3 x service life of the cutting unit components

- Chamfered-style cutting blade consistently stays in contact with the screen

- Improved cutting performance is achieved with the cutting blade maintaining optimal sharpness

- Uses 50% less power for 50% longer usage (35L oil flow per min)

- Heavy-duty rotor and adjuster spring design

Efficient horizontal slurry distribution with variable spreading rate

DosiMat DMX

- Best distribution accuracy thanks to the flow-optimised rotor contour for use in the field of injection technology

- Consistently high distribution accuracy regardless of the flow rate

- Long service life of the cutting tools of up to 200,000 m3 per macerator

- Service friendly design for easy maintenance of all components

- Advanced cutting blade contour for reliable shredding and flow of slurry

- Air suction: Patented membrane for automatic regulation of air flow

- Reduced weight of up to 25% through selection of materials

- Maximum operational safety with sealing package between the housing and the hydraulic motor

The slurry macerator without air suction

ExaCut ECC

- Innovative Air-Free Design: No need for ventilation hoses and air suction, preventing negative pressure and ensuring smoother slurry distribution

- Designed for Tough Conditions: Engineered and tested cutting principle for Ireland to withstand demanding slurry environments

- Proven maintenance concept: Easy and unique rotor maintenance in less than 20 minutes without removing a single hose

- Very smooth slurry distribution without pulsation of the hoses

- Developed for the use of injection machines and cultivators

- Cross-sections up to 150 DN for maximum effectiveness and user-friendly eccentric activation

- Efficient and Low-Cost Operation: Reduced power and oil requirements while maintaining optimal performance - only 35 l oil capacity

The classic Vogelsang macerator with optimal cutting results and reliability

ExaCut ECL

- Proven 10,000 times over making it the best-selling macerator in the world

- Tried and tested in demanding slurry environments in Ireland over 15 years

- Vertical rotor with self-sharpening cutting blades, macerates, separates, and distributes slurry in one step

- Easy maintenance: Quick part changes without disassembly

- Robust and compact design with high-quality materials to handle local slurry conditions

- Optimal hydraulic drive motor running around 35L/min

- Self-sharpening cutting tools: Reversing the rotation direction maintains a constant degree of sharpness over the entire lifetime

- Sealing package between the housing and the hydraulic motor for maximum operational safety

- Excellent distribution accuracy and maceration

Macerator without air suction in a compact space

ExaCut ECM

- Precise slurry distribution without aeration hoses and air suction

- Innovative rotor concept with high cutting power

- Our smallest and most compact macerator

- 30 % less weight due to space-saving housing

- Universally applicable and east to retrofit even with short hose paths

- Very good transverse slurry distribution already at 1500 l / min per macerator

- Continuous optimum degree of cutting knives sharpness due to change of direction of rotation

- Conical screens for optimum cutting results

Heavy Duty design with the best distribution accuracy

ExaCut ECQ

- Designed to handle tough fibre slurry conditions in Ireland

- Achieving 99% accuracy in slurry distribution to all hosepipes making it the most even and consistent distribution

- Easiest maintenance available on the market with convenient access to parts, ensuring fast servicing

- Long life of wearing parts with 3 x service life of the cutting unit components

- Chamfered-style cutting blade consistently stays in contact with the screen

- Improved cutting performance is achieved with the cutting blade maintaining optimal sharpness

- Uses 50% less power for 50% longer usage (35L oil flow per min)

- Heavy-duty rotor and adjuster spring design