Wet cutter with heavy material separator

RotaCut®

- Reliably macerates fibers and foreign matter in liquid media

- Protects downstream system components from damage caused by heavy matter

- Prevents blockages and clogging of pumps, fittings and pipe systems

- Reduces the viscosity and homogenizes liquids and suspensions

- Prevents floating layers

The RotaCut® macerator for homogeneous media and reliable plant protection

Whether in the food industry, pulp and paper industry or in abattoirs, efficient maceration of coarse matter and fibrous material in fluid media forms a key component of processes in many sectors. Smooth operation of biogas and sewage treatment plants depends on reliable heavy material separators and maceration of solid and disruptive matter in fluid media. Macerators also significantly impact the cost-effectiveness of agricultural businesses and disposal companies.

Vogelsang developed the RotaCut macerator 25 years ago, and continues to prove its reliability – under the most challenging conditions – round the world. From fecal matter, liquid manure and organic suspensions to potato pulp, food waste and abattoir waste through to sewage and oil sludge – the RotaCut’s universal suitability for an ever-expanding range of sectors and applications is constantly tested – and its effectiveness validated.

Its decisive advantage: the RotaCut separates critical heavy matter before the medium being prepared reaches the macerator’s cutter head. Thanks to clever details and sophisticated design, the RotaCut can even chop down hair and industrial fibers, thereby reliably protecting all downstream components from foreign matter, as well as fibrous and solid matter.

Models of the RotaCut®

The economical wet cutter

RotaCut® RC

The RC series RotaCut are the tried and tested basic version of the wet cutter RotaCut. With flow rates up to 600 m³/h, they deliver reliable and economical cutting of fibers and disruptive matter in straightforward applications, and also separate heavy material, thereby protecting downstream parts and components from damage, blockage and entangled material, e.g. in wastewater technology and industry. Thanks to diverse options, the RC series can be individually configured for the respective task. From cost-effective straightforward pump protection for temporary use through to reliable preparation of media in everyday operation. For drive power, there is a choice between hydraulic and geared motors. Thanks to the pivoting cutter head, maintenance and checking the cutter head is always easy, and if needed, the cutting blades and cutting screen can be quickly replaced.

Downloads

The economical wet cutter for demanding applications

RotaCut® RCpro

The RCpro series is designed for reliable and economical disintegrating of media with a high solids and fibrous matter content, e.g. in industry and biogas plants. The stable design of the cutter head, clever features such as the cutting screen support, as well as useful options for the cutting blades, blade rotors and cutting screen make the RCpro series an economical solution when conventional cutters are not powerful enough. With flow rates up to 600 m³/h, their robust design enables them to also be used on the discharge side (up to 3 bar is possible). In combination with the Compact XL heavy material separator, large amounts of heavy material in the medium can be reliably separated out. Maintenance and service are quickly and easily carried out by pivoting up the cutter head.

Downloads

The easy to maintain and user-friendly wet cutter

RotaCut® RCQ

The RCQ series RotaCut models feature easy to maintain and user-friendly design for sewage treatment plants and wastewater technology or industrial applications with flow rates up to 300 m3/h. The cutters can be easily and conveniently monitored online with modern control technology. With the optional ACC plus, the status of the cutting blades is also monitored and visualized on an external display. The operator therefore always knows what's going on; there's no need to interrupt operation or even open the cutter. In addition, this information can be displayed graphically by the control – which is very useful if you want to monitor and check the RotaCut centrally or by remote control. A message informs the operator when the blades require changing so that you can plan any spare part orders and maintenance well in advance. Thanks to the new design of RCQ series cutters, maintenance work and even replacement of cutting components themselves can be performed quickly on-site by the operator's personnel or by a service partner.

Downloads

The easy to maintain and operator-friendly wet cutter for demanding shredding applications

RotaCut® RCQpro

Efficient cutting of coarse and fibrous matter in liquid media with effective protection from foreign matter and heavy material – the wet cutter RotaCut units in the RCQpro series offer all of this – at flow rates up to 600 m3/h. They are the ideal solution for processing media with a high solids and fiber content reliably and cost-effectively while still maintaining excellent ease of maintenance and operation, e.g. in biogas plants or in the food industry. Thanks to their robust design, they can also be used on the discharge side (up to 4 bar is possible). RCQpro series cutters also support online monitoring of cutting blades status with the ACC plus – including via remote control. When combined with a PCU, the operator receives detailed information regarding the load of the cutter and the status of the cutting blades without having to interrupt cutter operation or open the wet cutter RotaCut itself. Thanks to the service-oriented concept, parts replacement, including replacement of the Quality Cartridge mechanical seal, can be carried out in a short time on-site.

Downloads

The most powerful wet cutter of the RotaCut series

RotaCut® RCX

The RCX series cutters represent the logical further development of the wet cutter RotaCut. For flow rates up to 1200 m³/h, they epitomize cost-effective cutting for rugged applications in tight spaces. The RCX types feature extremely robust motors as well as solid and sturdy design, allowing for use on the discharge side at up to 6 bar. A completely new concept has been developed for good service and maintenance accessibility despite the larger dimensions and weights: The pivoting service flap allows for easy access to the cutter and thanks to the horizontal arrangement, the cutting blade and screen can be replaced with just a few motions. All RCX types feature a cartridge mechanical seal that requires less time to change, enhances reliability and increases maintainability overall.

Downloads

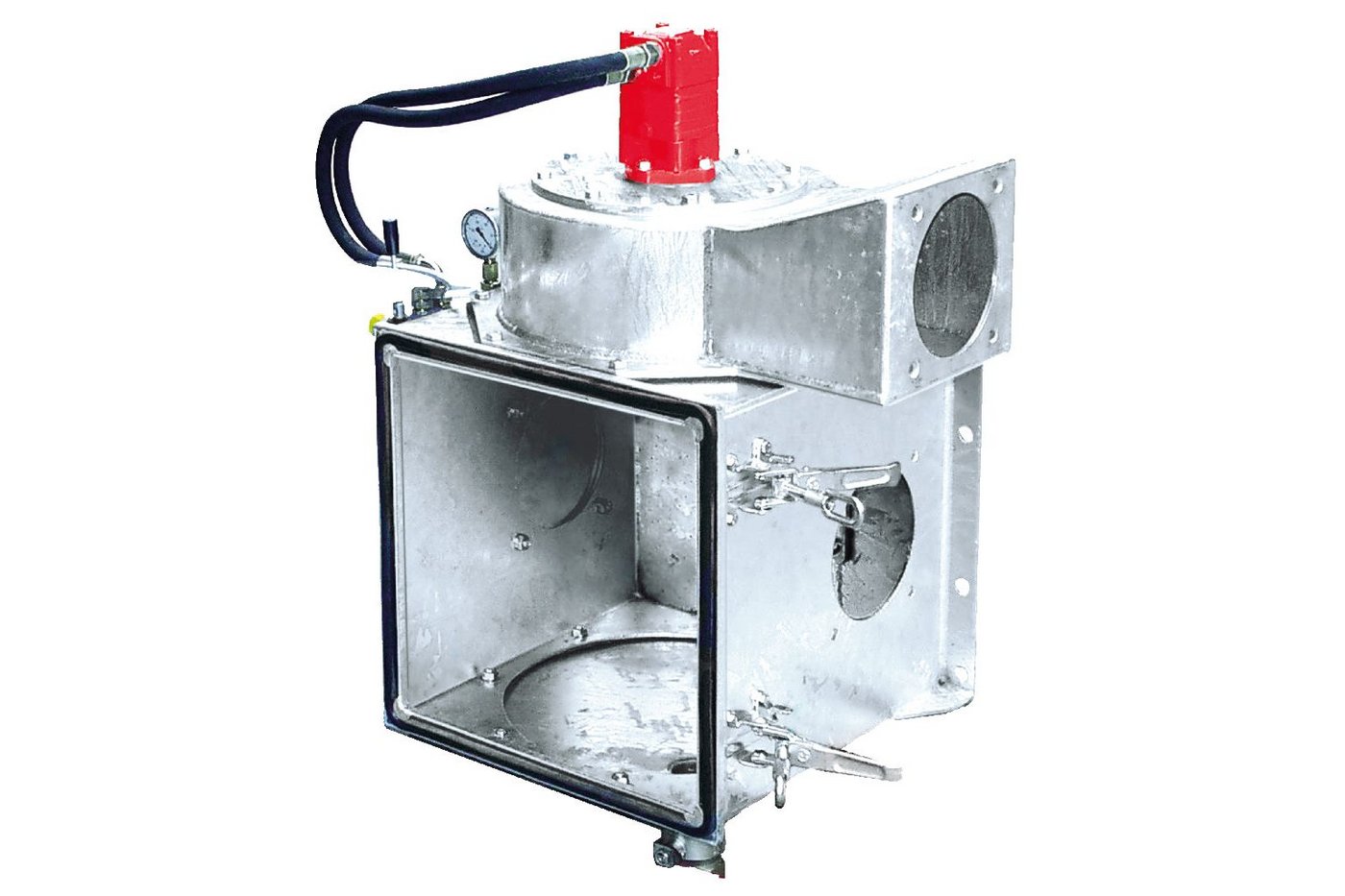

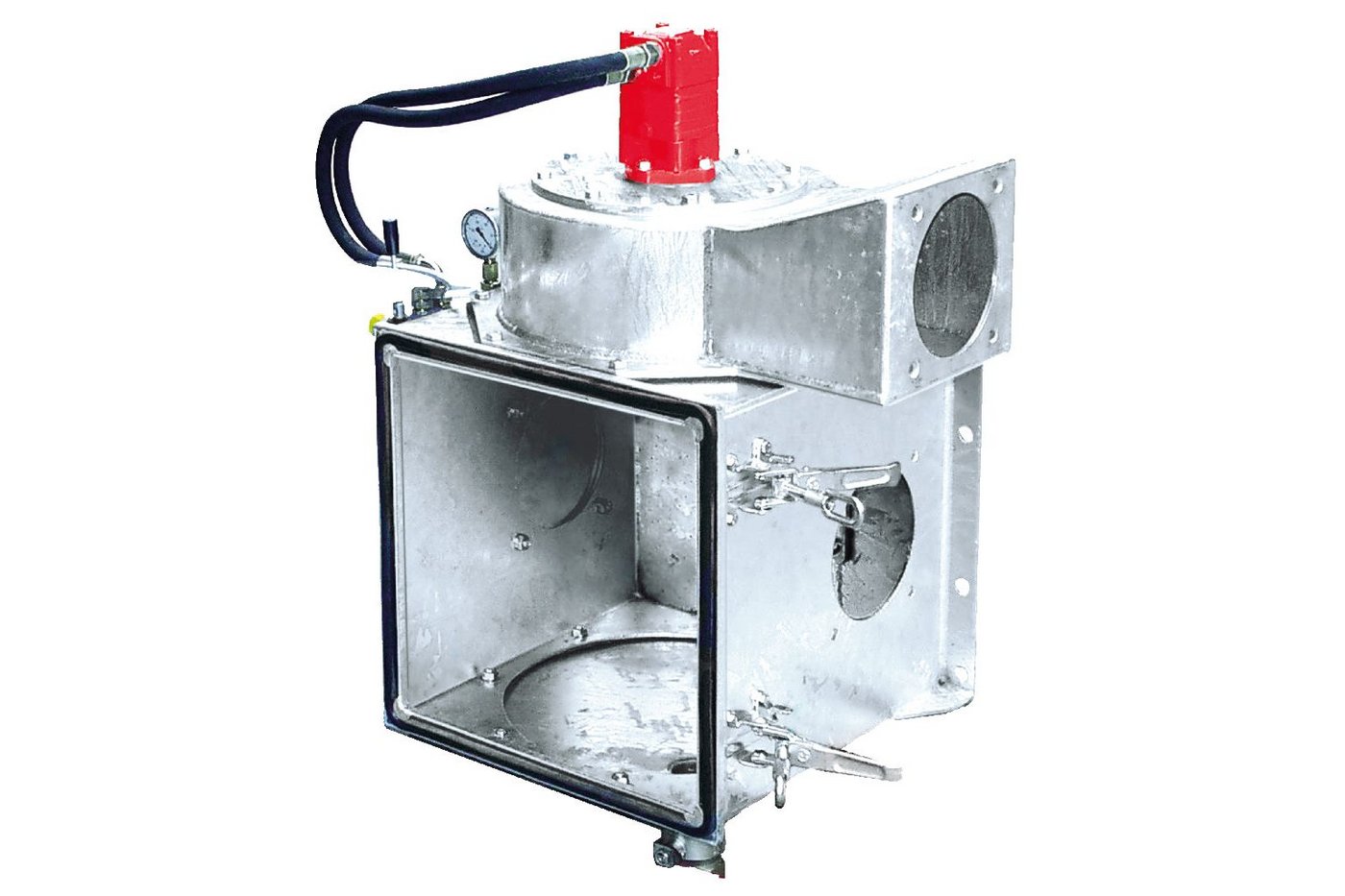

The wet cutter solution for tankers

RotaCut® MXL

In developing the wet cutter RotaCut MXL, special attention was paid to taking into account the exigencies of vehicle design. The design was specially developed for mobile use on tankers, delivers throughput up to 780 m3/h and can be quickly and easily integrated into the vehicle. The wet cutter RotaCut also performs a range of essential functions for mobile applications: Foreign matter such as stones and metal parts are reliably retained in the generously dimensioned heavy material separator. When pumping liquid manure, for example, the wet cutter RotaCut MXL cuts the coarse matter and fibrous matter, thereby homogenizing the entire medium. Drive power is usually provided by the hydraulics available on most vehicles. After opening the generously dimensioned service flap, the separated heavy material can be easily removed, and access to the cutter head for service and maintenance is enabled.

Downloads

The economical wet cutter

RotaCut® RC

The RC series RotaCut are the tried and tested basic version of the wet cutter RotaCut. With flow rates up to 600 m³/h, they deliver reliable and economical cutting of fibers and disruptive matter in straightforward applications, and also separate heavy material, thereby protecting downstream parts and components from damage, blockage and entangled material, e.g. in wastewater technology and industry. Thanks to diverse options, the RC series can be individually configured for the respective task. From cost-effective straightforward pump protection for temporary use through to reliable preparation of media in everyday operation. For drive power, there is a choice between hydraulic and geared motors. Thanks to the pivoting cutter head, maintenance and checking the cutter head is always easy, and if needed, the cutting blades and cutting screen can be quickly replaced.

Downloads

The economical wet cutter for demanding applications

RotaCut® RCpro

The RCpro series is designed for reliable and economical disintegrating of media with a high solids and fibrous matter content, e.g. in industry and biogas plants. The stable design of the cutter head, clever features such as the cutting screen support, as well as useful options for the cutting blades, blade rotors and cutting screen make the RCpro series an economical solution when conventional cutters are not powerful enough. With flow rates up to 600 m³/h, their robust design enables them to also be used on the discharge side (up to 3 bar is possible). In combination with the Compact XL heavy material separator, large amounts of heavy material in the medium can be reliably separated out. Maintenance and service are quickly and easily carried out by pivoting up the cutter head.

Downloads

The easy to maintain and user-friendly wet cutter

RotaCut® RCQ

The RCQ series RotaCut models feature easy to maintain and user-friendly design for sewage treatment plants and wastewater technology or industrial applications with flow rates up to 300 m3/h. The cutters can be easily and conveniently monitored online with modern control technology. With the optional ACC plus, the status of the cutting blades is also monitored and visualized on an external display. The operator therefore always knows what's going on; there's no need to interrupt operation or even open the cutter. In addition, this information can be displayed graphically by the control – which is very useful if you want to monitor and check the RotaCut centrally or by remote control. A message informs the operator when the blades require changing so that you can plan any spare part orders and maintenance well in advance. Thanks to the new design of RCQ series cutters, maintenance work and even replacement of cutting components themselves can be performed quickly on-site by the operator's personnel or by a service partner.

Downloads

The easy to maintain and operator-friendly wet cutter for demanding shredding applications

RotaCut® RCQpro

Efficient cutting of coarse and fibrous matter in liquid media with effective protection from foreign matter and heavy material – the wet cutter RotaCut units in the RCQpro series offer all of this – at flow rates up to 600 m3/h. They are the ideal solution for processing media with a high solids and fiber content reliably and cost-effectively while still maintaining excellent ease of maintenance and operation, e.g. in biogas plants or in the food industry. Thanks to their robust design, they can also be used on the discharge side (up to 4 bar is possible). RCQpro series cutters also support online monitoring of cutting blades status with the ACC plus – including via remote control. When combined with a PCU, the operator receives detailed information regarding the load of the cutter and the status of the cutting blades without having to interrupt cutter operation or open the wet cutter RotaCut itself. Thanks to the service-oriented concept, parts replacement, including replacement of the Quality Cartridge mechanical seal, can be carried out in a short time on-site.

Downloads

The most powerful wet cutter of the RotaCut series

RotaCut® RCX

The RCX series cutters represent the logical further development of the wet cutter RotaCut. For flow rates up to 1200 m³/h, they epitomize cost-effective cutting for rugged applications in tight spaces. The RCX types feature extremely robust motors as well as solid and sturdy design, allowing for use on the discharge side at up to 6 bar. A completely new concept has been developed for good service and maintenance accessibility despite the larger dimensions and weights: The pivoting service flap allows for easy access to the cutter and thanks to the horizontal arrangement, the cutting blade and screen can be replaced with just a few motions. All RCX types feature a cartridge mechanical seal that requires less time to change, enhances reliability and increases maintainability overall.

Downloads

The wet cutter solution for tankers

RotaCut® MXL

In developing the wet cutter RotaCut MXL, special attention was paid to taking into account the exigencies of vehicle design. The design was specially developed for mobile use on tankers, delivers throughput up to 780 m3/h and can be quickly and easily integrated into the vehicle. The wet cutter RotaCut also performs a range of essential functions for mobile applications: Foreign matter such as stones and metal parts are reliably retained in the generously dimensioned heavy material separator. When pumping liquid manure, for example, the wet cutter RotaCut MXL cuts the coarse matter and fibrous matter, thereby homogenizing the entire medium. Drive power is usually provided by the hydraulics available on most vehicles. After opening the generously dimensioned service flap, the separated heavy material can be easily removed, and access to the cutter head for service and maintenance is enabled.

Downloads

Features of the RotaCut®

Options of the RotaCut®