Industriepumpen für Ihre Anwendungen

Drehkolbenpumpen der VX-Serie für Anwendungen in den unterschiedlichsten Industrien

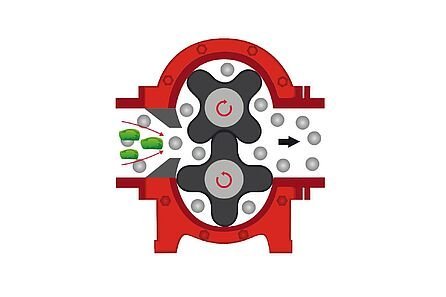

Die Drehkolbenpumpen der VX-Serie sind die perfekte Lösung für eine Vielzahl von industriellen Anwendungen. Sie können beispielsweise für das Verpumpen von viskosen Medien wie Öl in der Petrochemie oder Molasse in der Zuckerindustrie genutzt werden. Flüssigkeiten wie beispielsweise in der Weinindustrie, die einen hohen Feststoffanteil wie Bodensatz oder Trester enthalten, können ebenso gut gefördert werden wie Abwasseröle bei Recycling-Anwendungen oder Medien in einer potentiell explosiven Umgebung (ATEX). Dank der Trockenlaufunempfindlichkeit

und der Fähigkeit drehrichtungsunabhängig zu fördern, sind die Industriepumpen

der VX-Serie die beste Lösung für das Füllen und Löschen von Tanks in Lagerräumen, Tankwagen oder Schiffen.

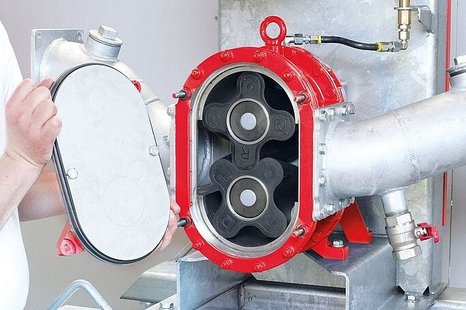

Das kompakte und platzsparende Design ermöglicht, dass diese Drehkolbenpumpen in jedes System integriert werden können. Dank weiterer Innovationen wie dem patentierten InjectionSystem oder den einmaligen HiFlo-Kolben garantieren die Industriepumpen der VX-Serie eine maximale Effizienz für den Betrieb. Außerdem haben wir das QuickService-Konzept entwickelt, wodurch die Verfügbarkeit der Anlage weiter gesteigert wird: Wartungsarbeiten sind schnell und direkt vor Ort vorgenommen, ohne dass die Drehkolbenpumpe ausgebaut werden muss. Mit fünf verschiedenen Baureihen und mehr als 25 unterschiedlichen Baugrößen für die robuste, technisch hervorragend konstruierte und leistungsfähige Pumpentechnologie haben wir die perfekte Pumpe für jede Anwendung.